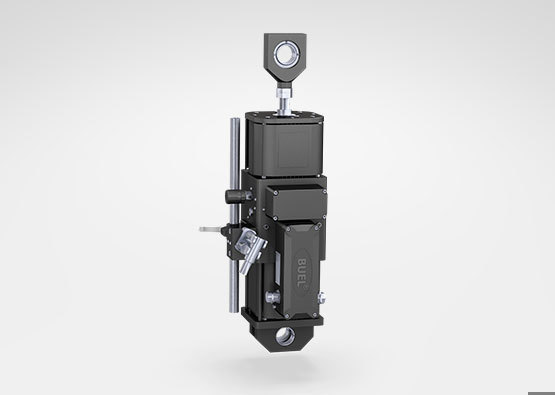

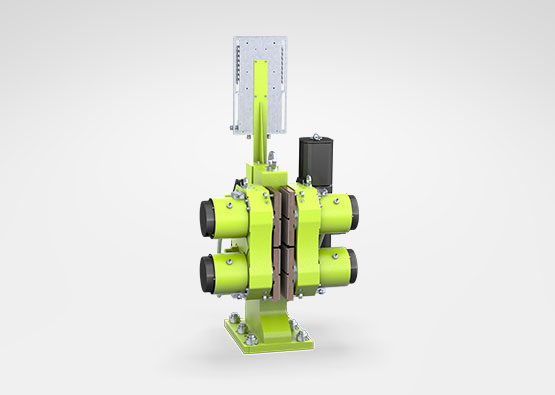

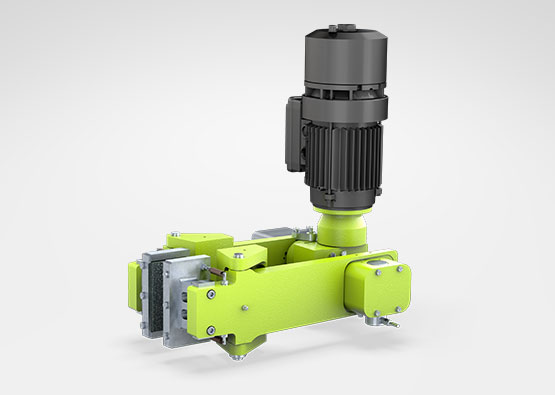

Buel® S

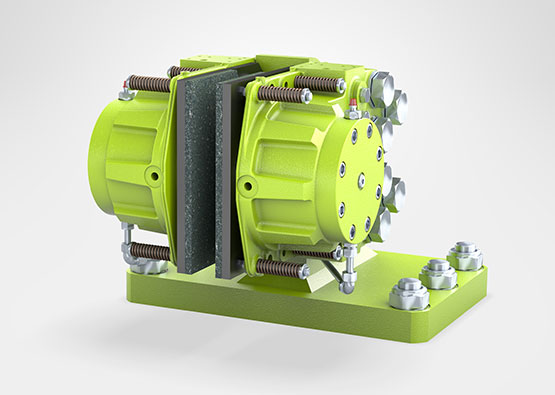

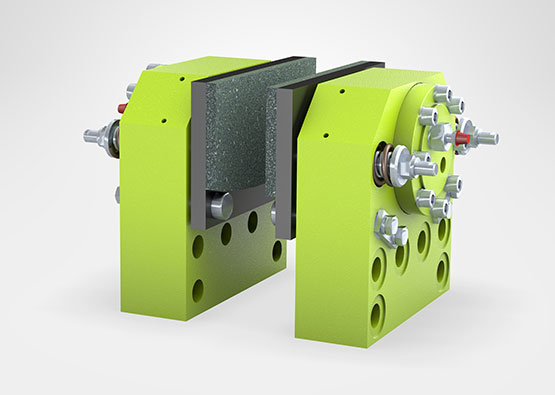

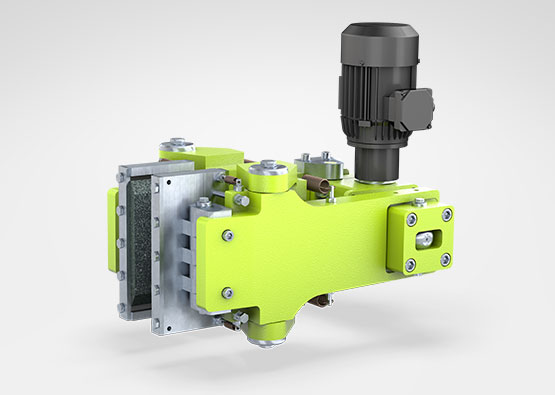

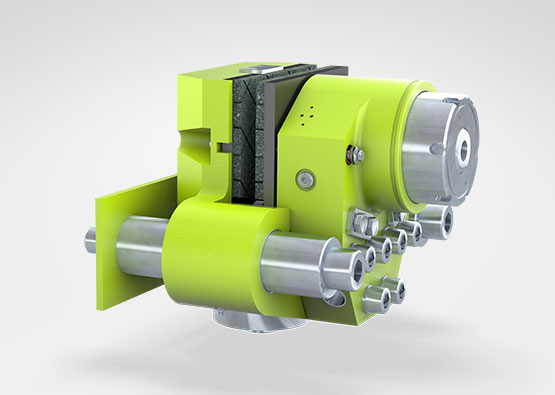

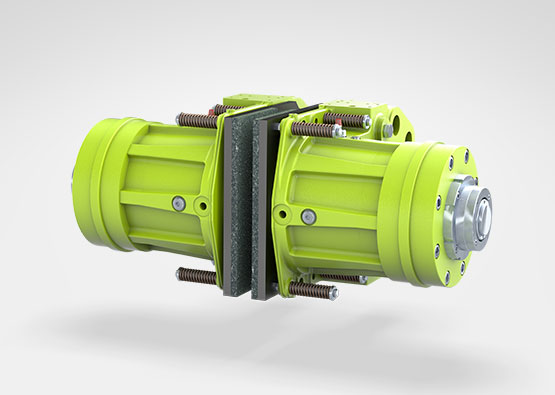

The BUEL® Model S is a brand new family member of the DELLNER BUBENZER brand BUEL®. It is designed for wheel brakes on rail mounted cranes, where high pulling forces for mechanical wheel brakes are required. The patented cylinder system generates pulling forces up to 40.000 N. It has a robust, but also compact design for rough environmental conditions.

- Pressure generation by centrifugal gear pump

- Energy saving by intermittent duty

- Fail safe principle

- Redundant valves

- Terminal box with control board

- Automatic pressure drop compensation

- Low heat generation

- Huge temperature range in standard execution

- Little oil volume

- Low ecologic risk

- High protection category

- Infinitely variable setting time

- Hand pump with shut-off valve

- Low weight, excellent mass/performance ratio

- Limit switch release control off the shelf

Electrical design All BUEL® Model S units are operated with 3-phase voltages between 220 V to 690 V @ 50 Hz or 60 Hz.

Protection class The electric components of the BUEL® Model S thrusters are located inside, for best protection against environmental influences. BUEL® thrusters are rated IP 65.

Protection class IP 67 is available as an option.

Operating modes BUEL® Model S thrusters are designed for intermittent duty, independently from the required operating mode of the drive installed. There is no limitation of the duty cycle.

After reaching the working pressure, the motor is switched off. In case the working pressure is not reached within 4 seconds, the motor is switched off internally.

Ambient temperature range BUEL® Model S thrusters are suitable for ambient temperatures between -30°C to +60°C. For deviating ambient temperatures, please contact us for support.

Protection against moisture For applications in maritime or tropic environments, the optional use of a small heater to protect the motor windings from moisture is recommended.

Heater voltages can be:

- 110 to 120 V AC 50 Hz or 60 Hz

- 220 to 240 V AC 50 Hz or 60 Hz

Hydraulic media BUEL® Model S thrusters are filled with a high performance synthetic oil, type Fuchs Titan CHF 11S. This oil insures a trouble-free operation in the entire temperature range, indicated above.

Biodegradable oil is available as an option.

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

Supported by decades of engineering, evolution, and innovation, the SB 28.5 brake presents significant advantages with an enhanced and compact design, sustainability, and preeminent performance.

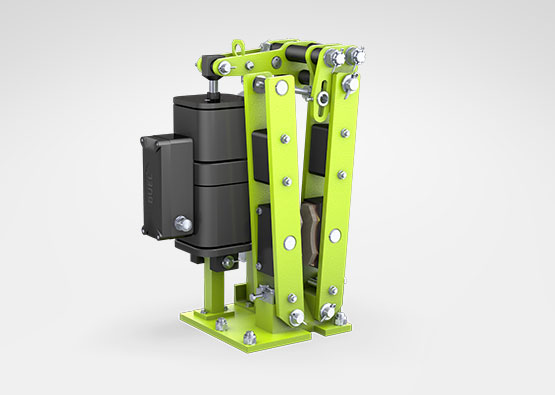

The SB 30 is the most powerful service brake in this series. It is dimensioned for large hoists and for BOSS applications. Furthermore, automatic adjustment, self-centering, jaw parallel adjustment are part of the standard equipment.

The SB 8 series covers a large part of the versatile industrial applications. It is often used in hoists where installation space is limited and can be equipped with a wide range of options.

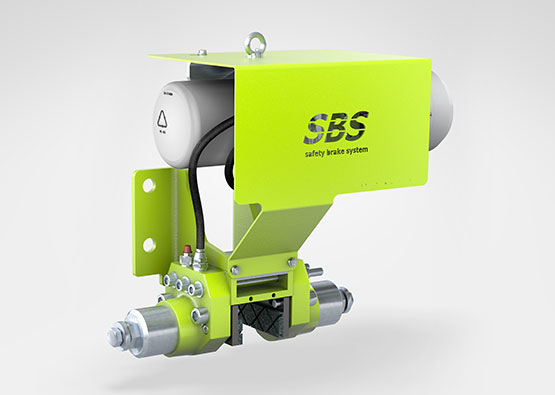

The SBS system consist of a spring applied, hydraulically released SKP model disc brake and the hydraulic brake release pressure is generated from a Hydraulic Power Pack – all incorporated on a bracket. The SBS is typically used on stacker cranes (bolted to crane structure) and the brake is acting directly on the crane travel railhead. The system communicate with the crane control system and can stop the crane wherever in the aisle in an emergency situation.

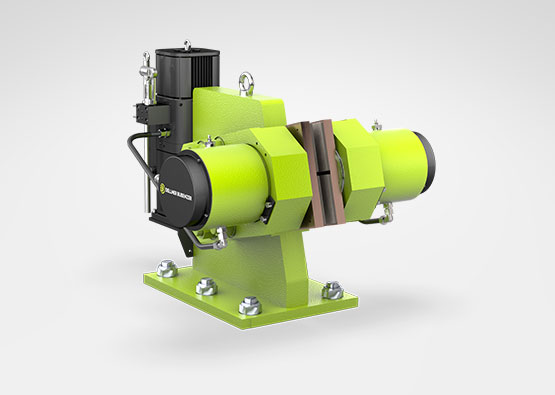

The high capacity of the SF-series makes them particularly suitable as secondary emergency brakes on hoist gears and on downhill conveyors.

The high capacity of the SF-series makes them particularly suitable as secondary emergency brakes on hoist gears and on downhill conveyor.

For many years a seawaterproof version of the SFB series has been used successfully on winch motors in ship building and as a safety, service or holding brake in wharf crane installations.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKDe disc brakes are direct acting electric applied, spring released units.

DELLNER BUBENZER's model SKDe disc brakes are direct acting electric applied, spring released units. The braking force achieved is directly proportional to the applied pressure.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

With a single acting (SA) brake, braking force is generated in one half of the brake and the other half slides towards it using a robust, low friction system, enabling self-alignment and making it ideal for small spaces and applications with axial movement.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.