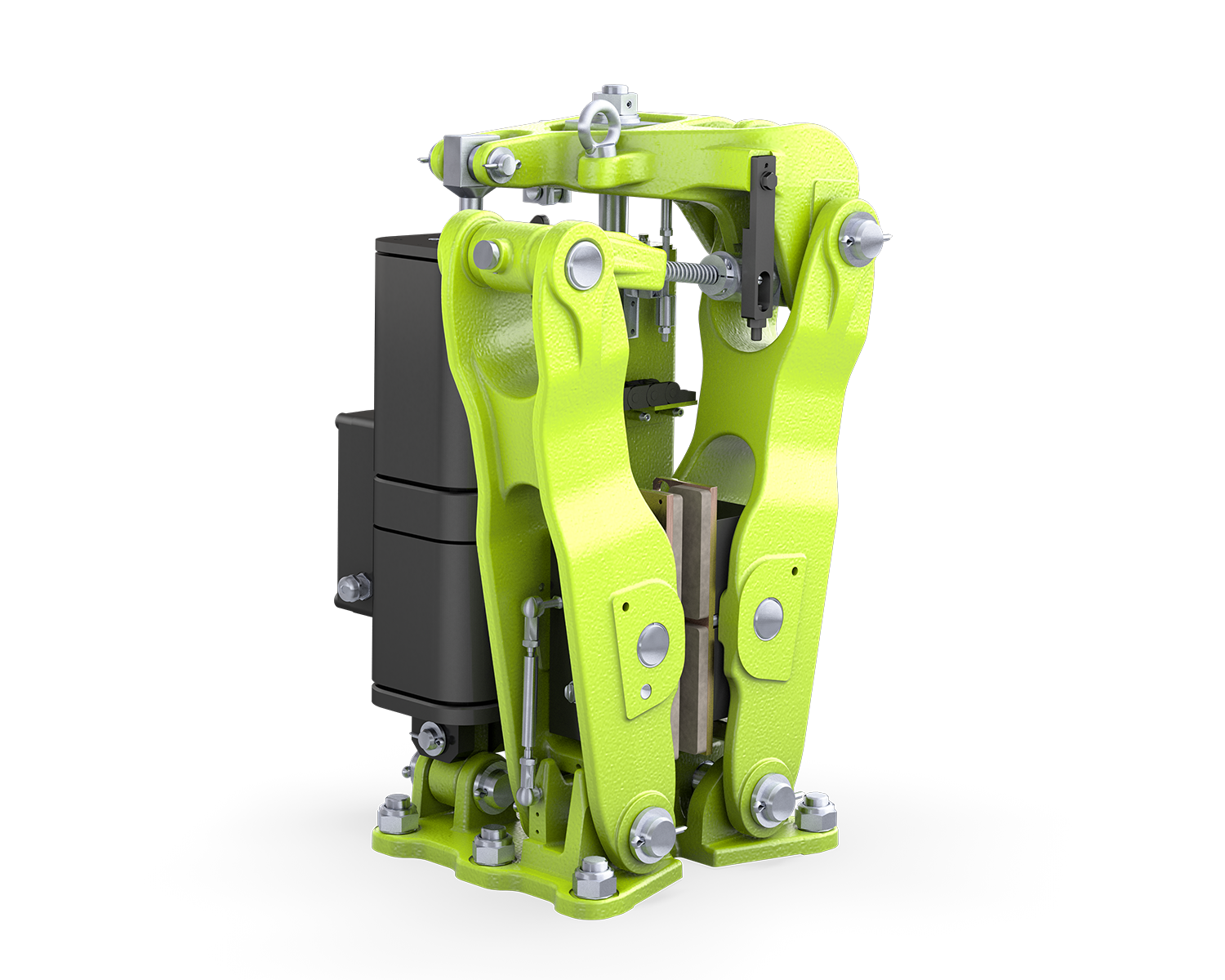

SB 28.5

- Torque:

- 23400 Nm

- Contact Force:

- 65000 N

To uphold our reputation as a global leader in braking systems and manufacturing solutions, the SB 28.5 represents DELLNER BUBENZER’s commitment to constantly innovate, provide industry solutions and anticipate the needs of our customers. Supported by decades of engineering, evolution, and innovation, the SB28.5 brake presents significant advantages with an enhanced and compact design, sustainability, and preeminent performance. Welcome to the SB 28.5, the new generation of SB-disc brake series.

- Proximity switch brake release

- Manual release lever with or without lock

- Manual release lever latching or non latching

- Automatic wear compensator

- Sintered linings for high friction speeds

- Continuously adjustable brake spring with torque scale and wear bushing enclosed in a spring tube

- Stainless steel pins and spindles

- W-execution (special anti-corrosion protection)

- Maintenance-free bushings in all hinge points

- Symmetric design

- Parallel air gap when brake is released (no tipping of the brake shoes)

- Proximity switch pad wear

- Proximity switch hand release

- Monitoring systems (e.g. VSR/CMB)

- Brake disc with hub or coupling

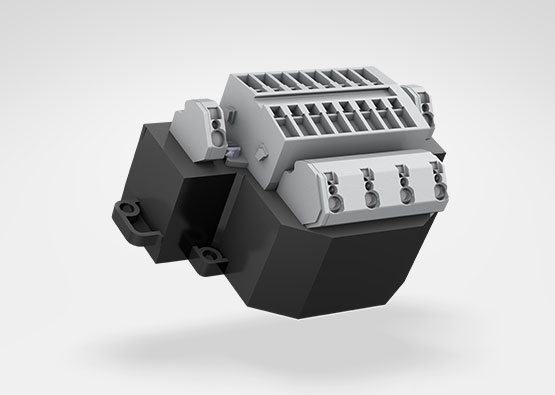

- Option: Terminal box for limit switches

- Special painting for increased corrosion protection

- Manual release lever on top of BUEL® thruster

SB 28.5 FEATURES

Sustainability

Developed on the foundation of decades of experience in power transmission, BUEL® sets the industry standard for reliability, safety, and environmental impact.

- BUEL® Thruster & Reduced Energy Costs

- Reduced Fluid Volume

- Eco-friendly Biodegradable Oil

SB 28.5 FEATURES

Enhanced Design

Supported by decades of engineering, the SB 28.5 brake presents significant advantages with preeminent performance and sustainability.

- Facelift, Weight Savings & Reduced Carbon Footprint

- 101 Interchangeability

- Easy Installation & Commissioning

SB 28.5 FEATURES

Automated Wear Compensation

Upgrading our products for optimal performance potential, expands and enhances our product portfolio with precision and expertise.

- Freewheel-based Automatic Wear Compensator

- Easy Maintenance

SB 28.5 FEATURES

Improved Self-Centering System

To uphold our reputation as a global leader, we deploy the latest in technology and mirror what the market needs, and our clients deserve.

- New & Upgraded System by Roller & Cam

- Equal Air Gaps with Self-centering Brake Levers

SB 28.5 FEATURES

Enhanced Parallel Alignment System

- Symmetric Designed Brakes

- Brakes Shoes are Parallel Positioned to the Brake Disc

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

Half Wave & Full Wave rectifiers for Din rail or panel mounted rectification.

Gas-hydraulic buffers are installed as impact energy absorber on crane gantries, trolleys, elevators, stackers, reclaimers and other industrial equipment.

Protective element to be connected parallel to the output of the rectifiers BGL, EGL and SGL to increase the interurruption capacity

Din rail mounted unit switches from bridge rectification to half-wave rectification

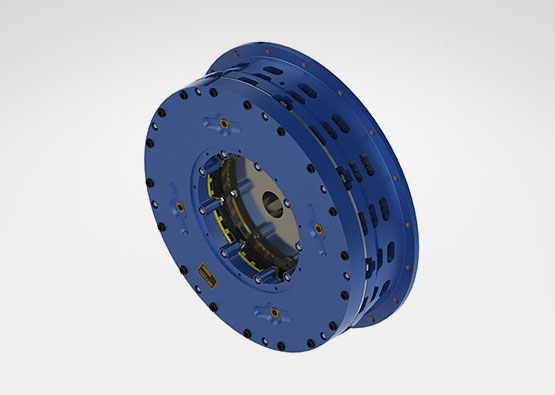

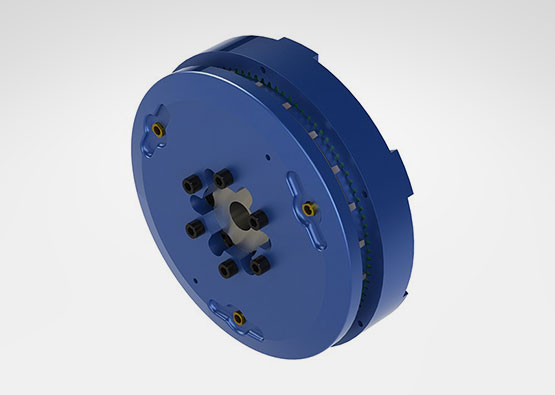

WPT Low Inertia Brakes are suited for high cycle applications or general brake duties. These heavy duty brakes afford increased precision for your processes with minimal part movement during start and stop, acceleration time is decreased leading to more cycles per minute.

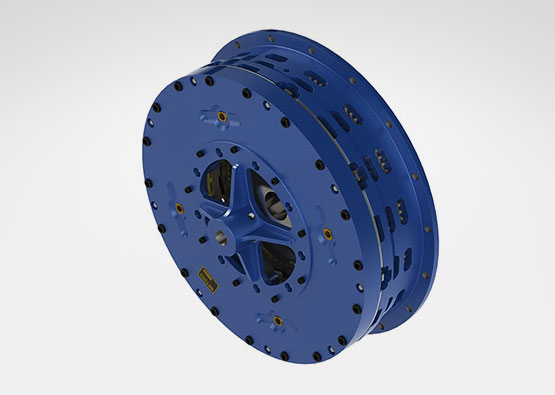

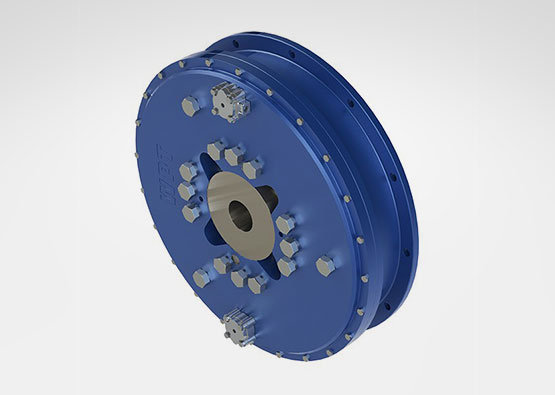

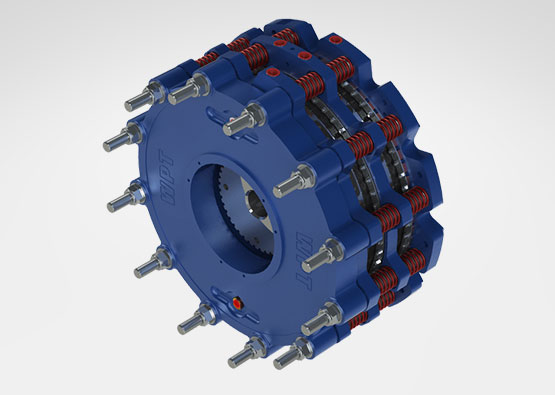

WPT Low Inertia Clutches and Brakes are suited for high cycle applications or general clutch/brake duties.

WPT Low Inertia High Torque Clutches are suited for high cycle applications or general clutch duties.

This flywheel PTO is designed for inline and sideload applications on all internal combustion engines with standard SAE industrial flywheel or flywheel housing dimensions.

WPT Power has engineered the WPT Pilotless™ Mechanical Power Take-off to eliminates the pilot bearing and increases side load capacity over previous generations of PTO products.

WPT Planetary Hydraulic Hoists are ideal for applications in the oil & gas, utility, and crane industries. WPT’s hoist designs adhere to SAE J706 standards and provide lifting capacities of 8,000 lbf and 12,000 lbf, respectively.

WPT Planetary Hydraulic Winches provide fast line speed and consistent, powerful pull capacity.

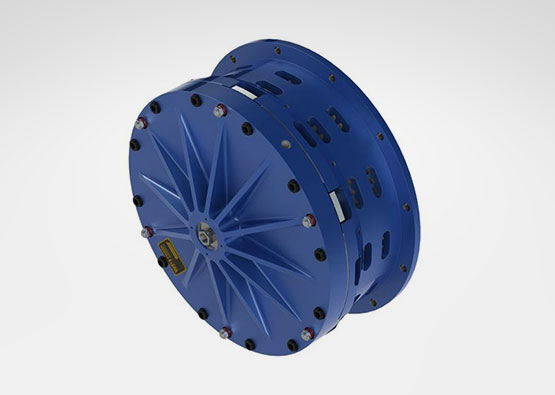

WPT® Power Grip clutches are designed to accommodate in-line and shaft-to-shaft power transmission applications with large inertia loads.

The WPT® Power Grip PO Clutch is suitable for in-line and shaft-to-shaft power transmission applications.

The WPT® Type 2 Hydraulic Power Take-Off utilizes large spherical roller bearings designed for heavier duty sideload capacity.

WPT® water cooled brakes (WCBs) are high energy absorbing solutions used as dynamic tensioning and static holding brakes.

WPT Worm Gear Winches are offered from 9,000 lbf to 20,000 lbf, with options of hydraulic or electric operation.