Braking Systems that Withstand the Elements

Whether by surface or underground mining, millions of tons of earth must be moved to extract targeted raw minerals and/or materials. Gigantic tunnel boring and cleaning machines, conveyor systems, bucket wheel excavators, special vehicles, material grading and separating systems are built to be in service for years and operate 24 hours a day. DELLNER BUBENZER's commitment to the highest quality manufacturing and advanced technical standards delivers industry-leading braking systems and components that withstand all the elements.

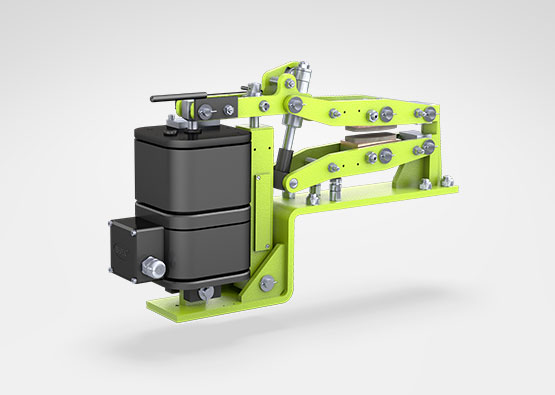

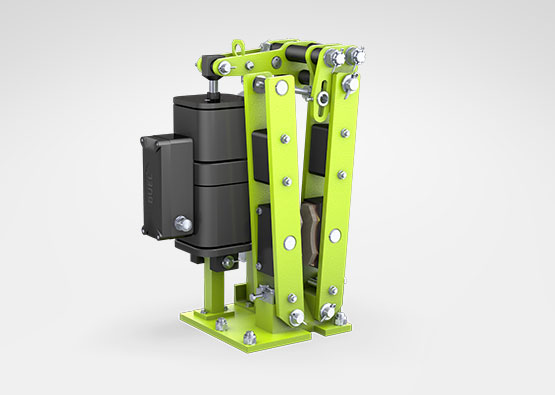

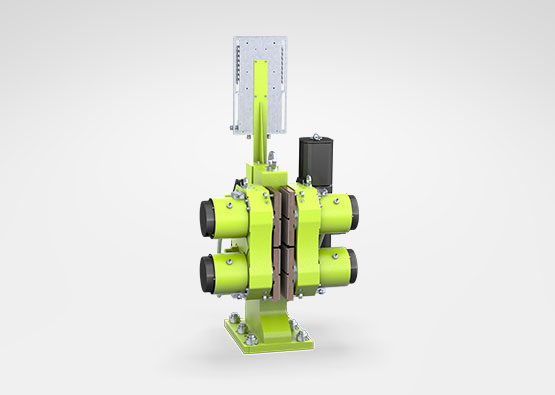

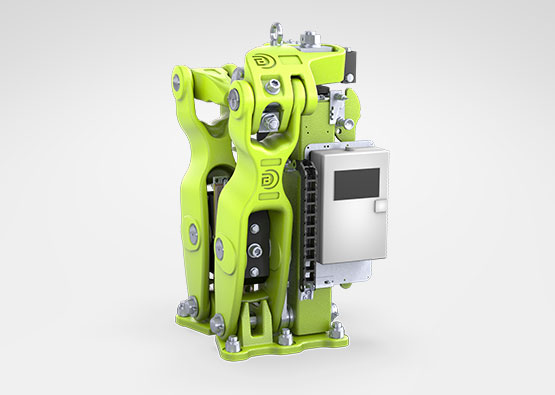

The high capacity of these brakes makes them particularly suitable as service- or secondary emergency brakes e.g. on hoists, slewing drives and belt conveyors.

The BUEL® Model G is a new family member of the DELLNER BUBENZER brand BUEL®. It is a compact thruster to feed active or passive hydraulic brakes and emergency brakes.

The BUEL® Model H is a family member of the DELLNER BUBENZER brand BUEL®. BUEL® thrusters are used for almost all kind of industrial applications.

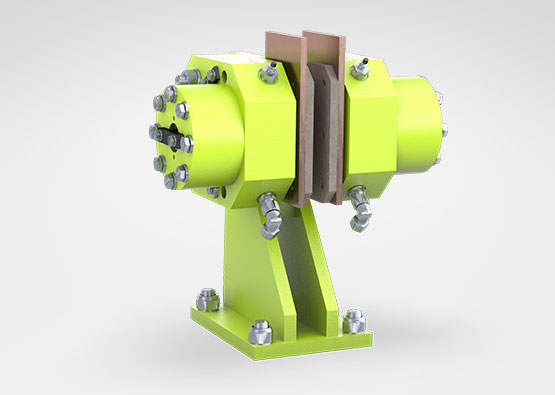

The EBH series is designed according to DIN 15435. This design is very compact and can be used in tight motor gearbox combinations.

The EBN series is designed according to DIN 15435 and has been in use in various industries for decades. EBN-2St modification: the drum brakes solution for Bridges and Sluice Systems

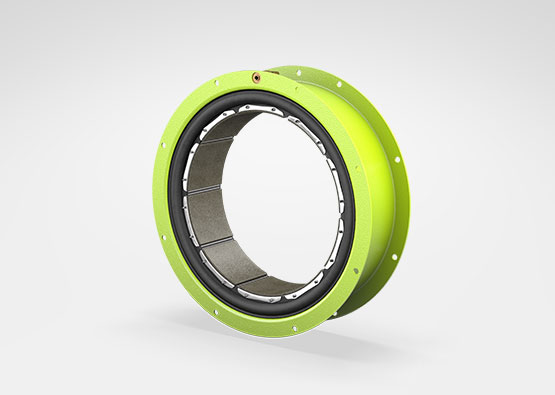

The FK is well suited as a clutch or brake for a variety of high speed and low to medium torque power transmission applications where high heat generation is not a factor.

The FKT is well suited for applications with the most demanding equipment where severe clutching and braking is required.

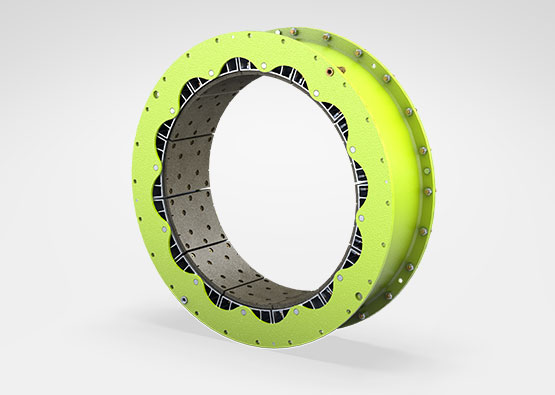

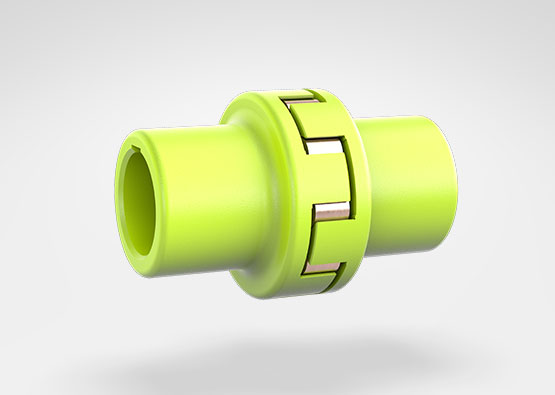

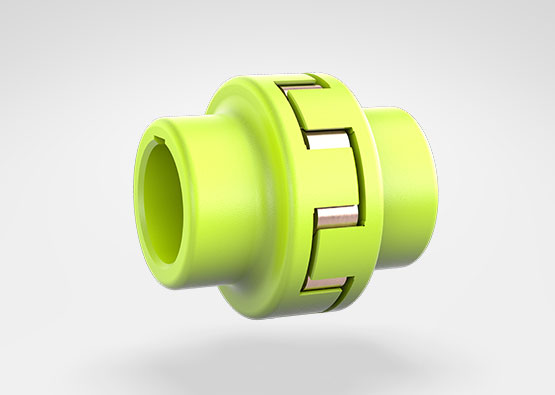

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

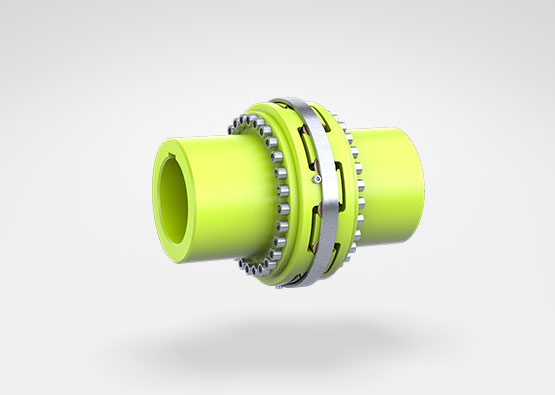

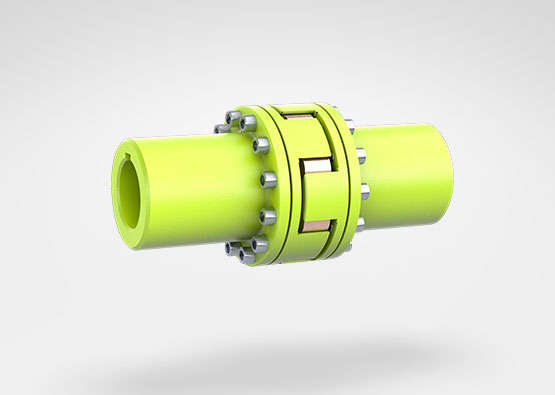

The KBSD Gear Couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

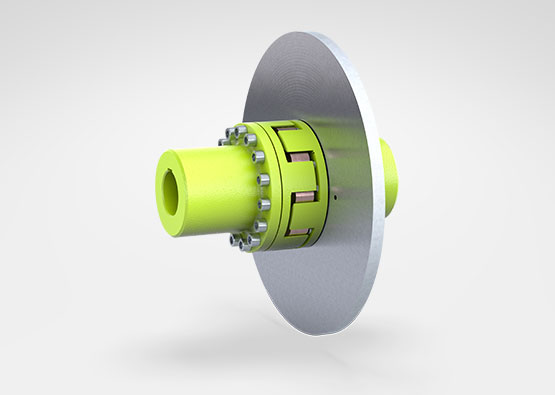

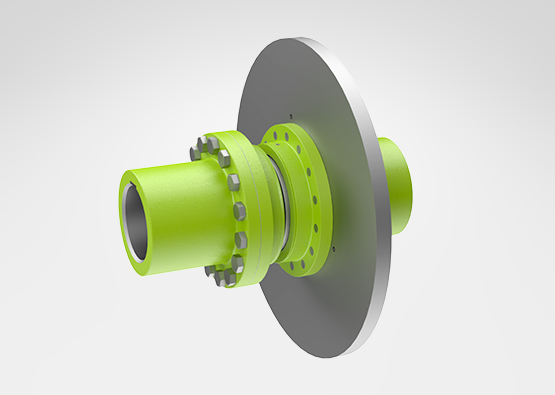

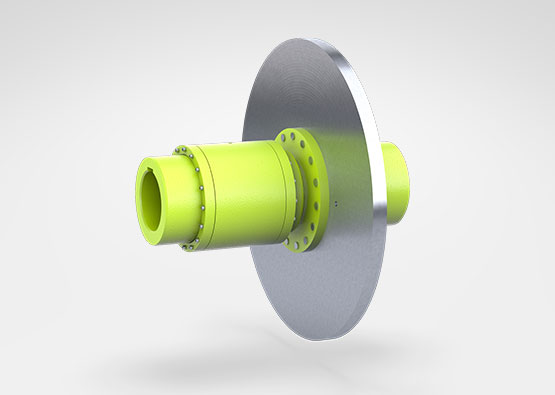

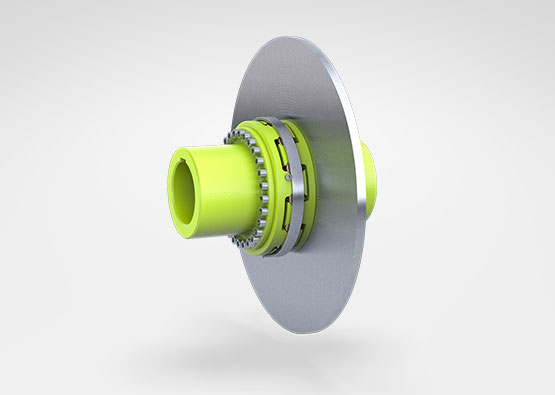

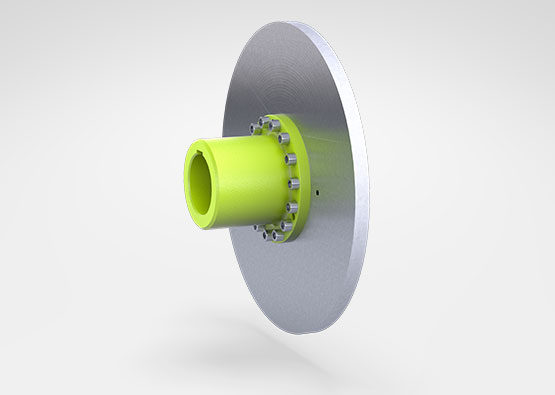

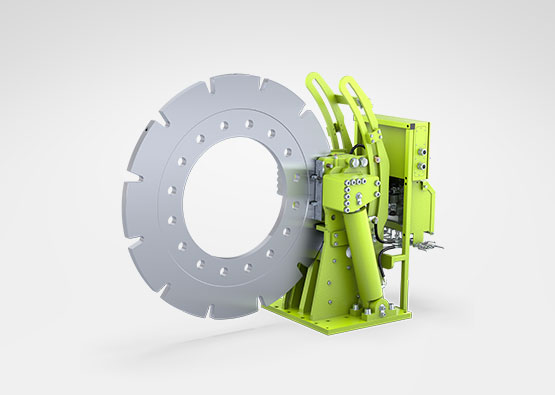

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

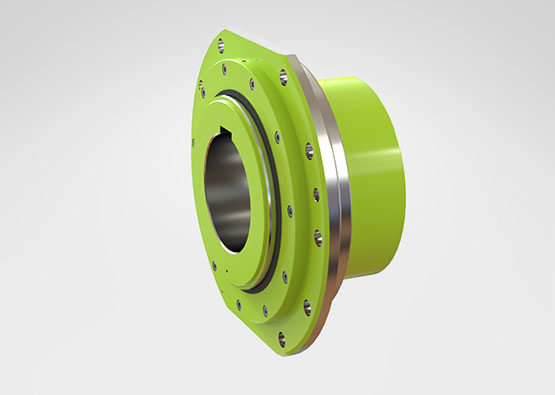

The NTRST Drum Couplings is a high-performance solution for hoist, winches, and conveying systems, ensuring a reliable connection between the gearbox output shaft and the rope drum. Designed to compensate for misalignments caused by bending drum structures, it enhances equipment lifespan and reduces wear.

The SB 16 brake has a very compact design and is often used on trolleys for container gantry cranes, RTG and RMG equipment

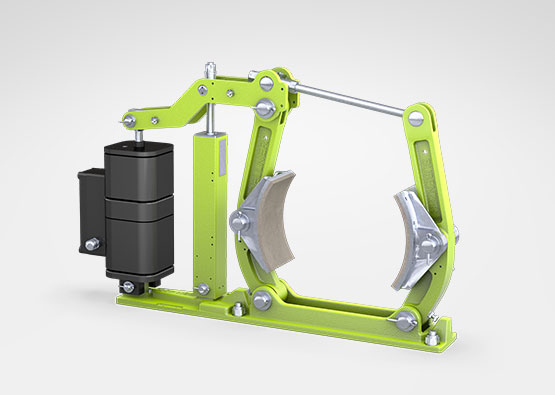

The SB 22 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

The SB 23.3 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

Supported by decades of engineering, evolution, and innovation, the SB 28.5 brake presents significant advantages with an enhanced and compact design, sustainability, and preeminent performance.

The SB 8 series covers a large part of the versatile industrial applications. It is often used in hoists where installation space is limited and can be equipped with a wide range of options.

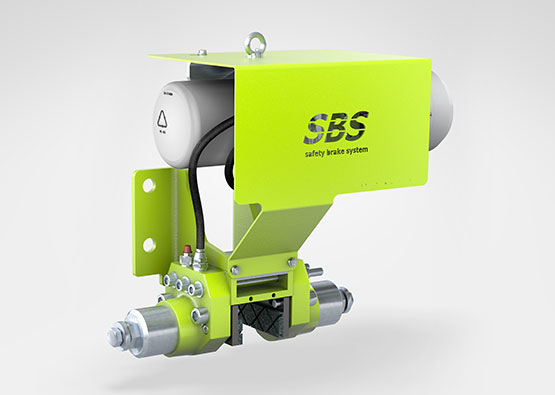

The SBS system consist of a spring applied, hydraulically released SKP model disc brake and the hydraulic brake release pressure is generated from a Hydraulic Power Pack – all incorporated on a bracket. The SBS is typically used on stacker cranes (bolted to crane structure) and the brake is acting directly on the crane travel railhead. The system communicate with the crane control system and can stop the crane wherever in the aisle in an emergency situation.

The high capacity of the SF-series makes them particularly suitable as secondary emergency brakes on hoist gears and on downhill conveyors.

The high capacity of the SF-series makes them particularly suitable as secondary emergency brakes on hoist gears and on downhill conveyor.

For many years a seawaterproof version of the SFB series has been used successfully on winch motors in ship building and as a safety, service or holding brake in wharf crane installations.

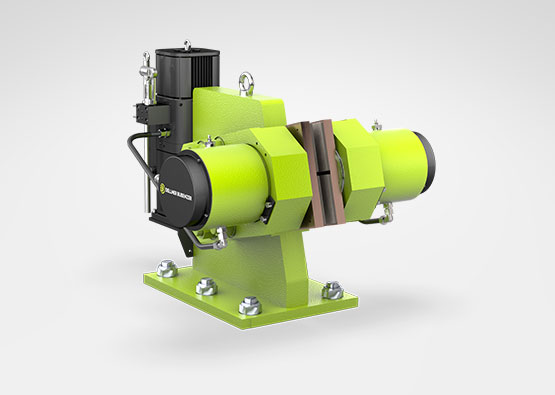

The STL Systems are "multi-function" units, all contained within one interface. It is indeed a modular system that you can choose the function(s) needed. All from single, S (Stopping) T (Turning) or L (Locking) functions.

A retrofitable, compact electronic status indication system to be integrated into the brake as an additional device.

Gas-hydraulic buffers are installed as impact energy absorber on crane gantries, trolleys, elevators, stackers, reclaimers and other industrial equipment.

Material Handling