Braking Systems that Perform in the Harshest Conditions

Hot, dusty conditions place tough demands on the drive systems and brakes used in steelmaking. Hot metal, semi-automated rolling mills and overhead loading cranes require the most reliable, maintenance-friendly braking systems possible. DELLNER BUBENZER’s engineers and designers apply years of experience to identify the problem areas and provide high-preformance, custom braking solutions for the iron & steel industry.

WPT Planetary Hydraulic Hoists are ideal for applications in the oil & gas, utility, and crane industries. WPT’s hoist designs adhere to SAE J706 standards and provide lifting capacities of 8,000 lbf and 12,000 lbf, respectively.

WPT Planetary Hydraulic Winches provide fast line speed and consistent, powerful pull capacity.

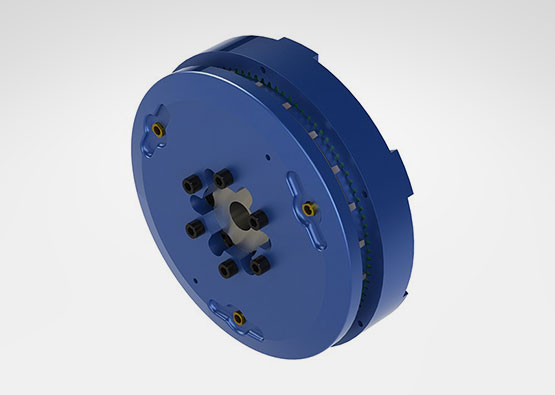

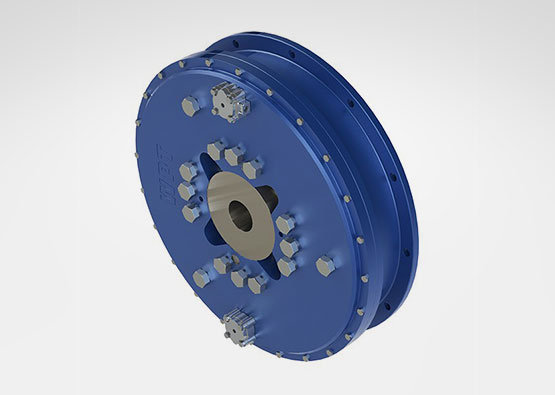

WPT® Power Grip clutches are designed to accommodate in-line and shaft-to-shaft power transmission applications with large inertia loads.

The WPT® Power Grip PO Clutch is suitable for in-line and shaft-to-shaft power transmission applications.

The WPT® Type 2 Hydraulic Power Take-Off utilizes large spherical roller bearings designed for heavier duty sideload capacity.

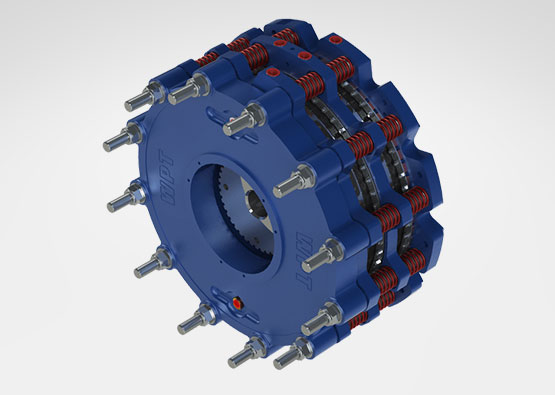

WPT® water cooled brakes (WCBs) are high energy absorbing solutions used as dynamic tensioning and static holding brakes.

WPT Worm Gear Winches are offered from 9,000 lbf to 20,000 lbf, with options of hydraulic or electric operation.

Iron & Steel