Braking Systems that Perform in the Harshest Conditions

Hot, dusty conditions place tough demands on the drive systems and brakes used in steelmaking. Hot metal, semi-automated rolling mills and overhead loading cranes require the most reliable, maintenance-friendly braking systems possible. DELLNER BUBENZER’s engineers and designers apply years of experience to identify the problem areas and provide high-preformance, custom braking solutions for the iron & steel industry.

DELLNER BUBENZER's Anti Sway Systems allow the damping of head-block, spreader and container oscillation generated by acceleration / deceleration of trolley and gantry.

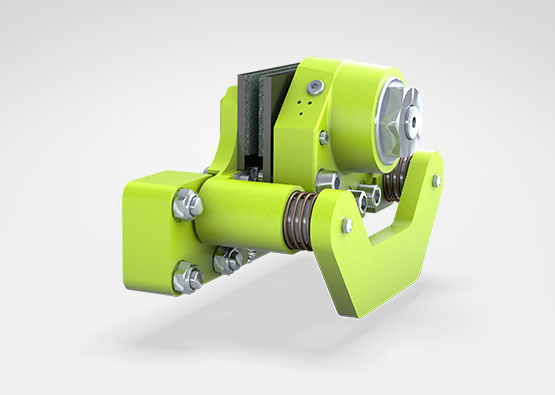

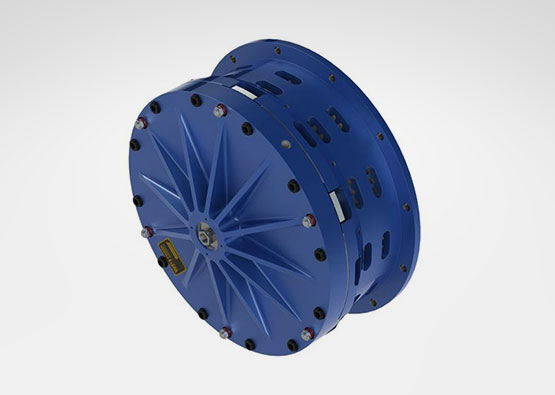

The BAC-brakes is used for stopping and/or holding of fans, blowers, wind turbines, coilers, crane slewing and travel gears etc.

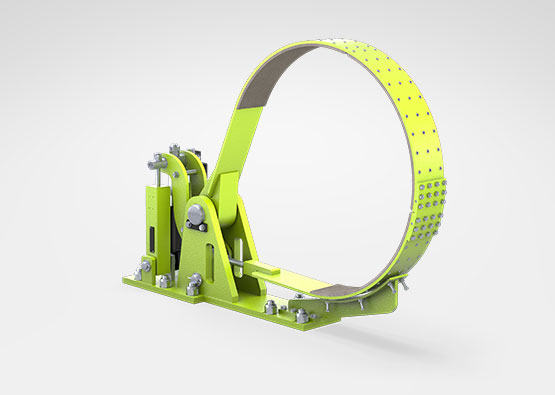

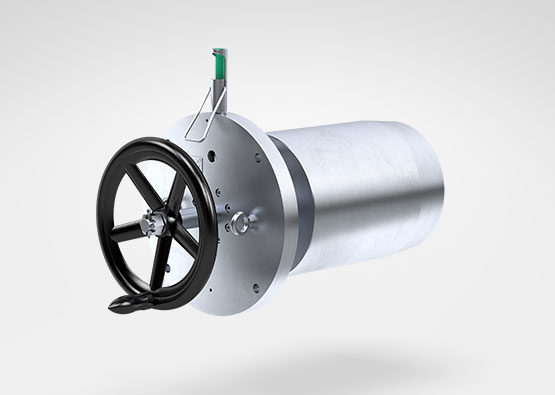

Band Brake for large torque applications that can be used for emergencies or back up braking needs. Band Brakes have been around for many years and we offer many ways to operate via thruster, air, hydraulic or hand wheel.

The BOSS® Brake Only Snag System system has been developed based on the experience with the SOS system that has been already installed in more than 200 container cranes world wide.

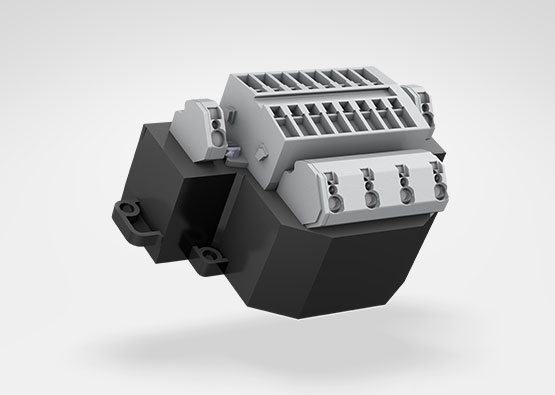

The BCMS-4 is a micro-controller-based monitoring and switching device for spring applied brakes of the SFB and KFB series.

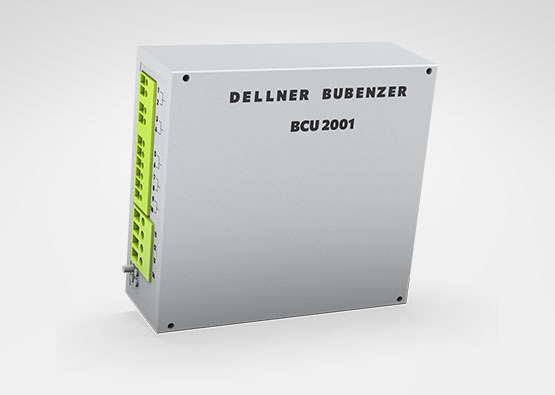

The Brake Control Unit BCU 2001 records characteristic current and voltage variations, which are induced by movements of the armature disk in the magnetic field of the brake coil.

These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic brakes to stop the crane. They are hydraulic powered with HPU or BUEL® G.

The high capacity of these brakes makes them particularly suitable as service- or secondary emergency brakes e.g. on hoists, slewing drives and belt conveyors.

The BUEL® Model G is a new family member of the DELLNER BUBENZER brand BUEL®. It is a compact thruster to feed active or passive hydraulic brakes and emergency brakes.

The BUEL® Model H is a family member of the DELLNER BUBENZER brand BUEL®. BUEL® thrusters are used for almost all kind of industrial applications.

Compact status monitoring system for a brake system with display and fieldbus interface.

Compact status monitoring system for a brake system with display and fieldbus interface.

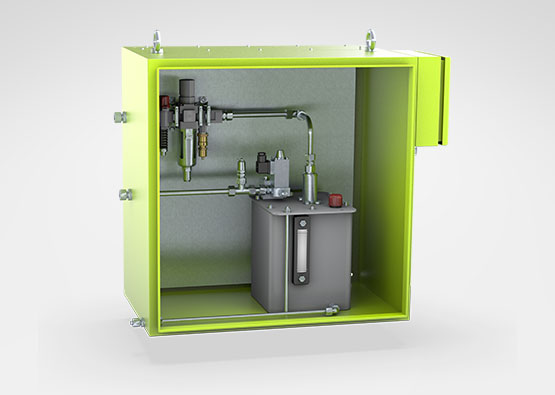

Compactus is a pneumatically operated hydraulic pump system that multiplies pneumatic line pressure into hydraulic pressure that is sufficient to operate pressure applied disc brakes at rated capacity.

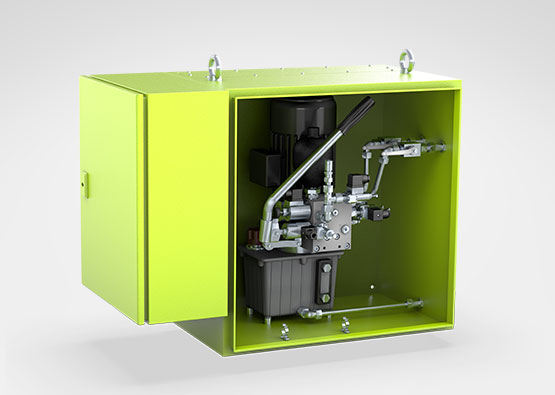

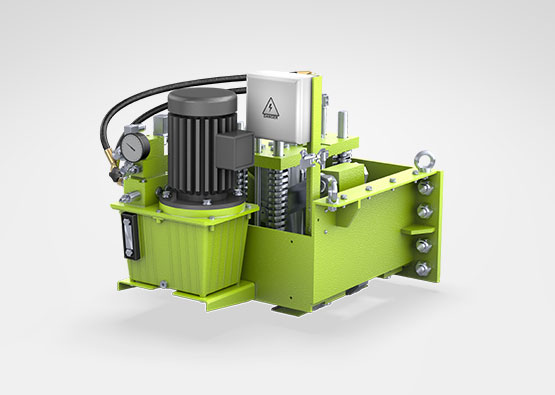

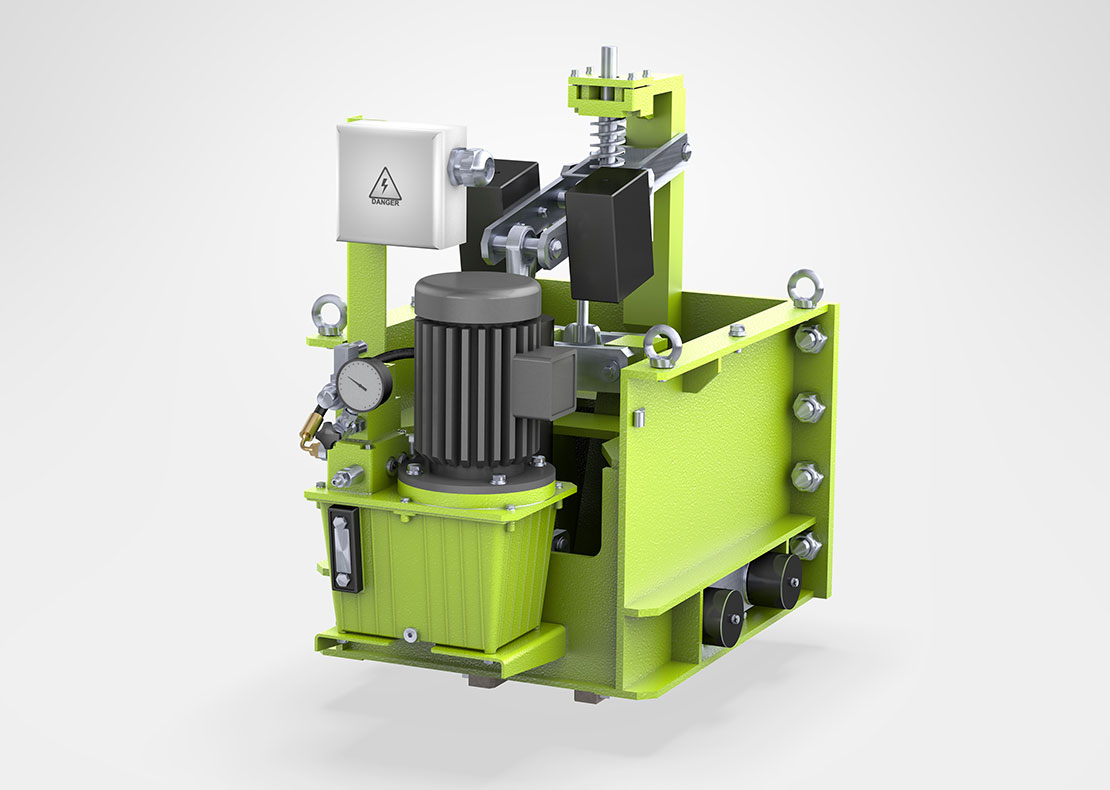

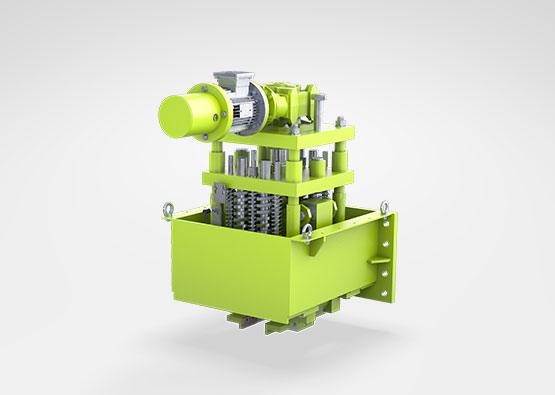

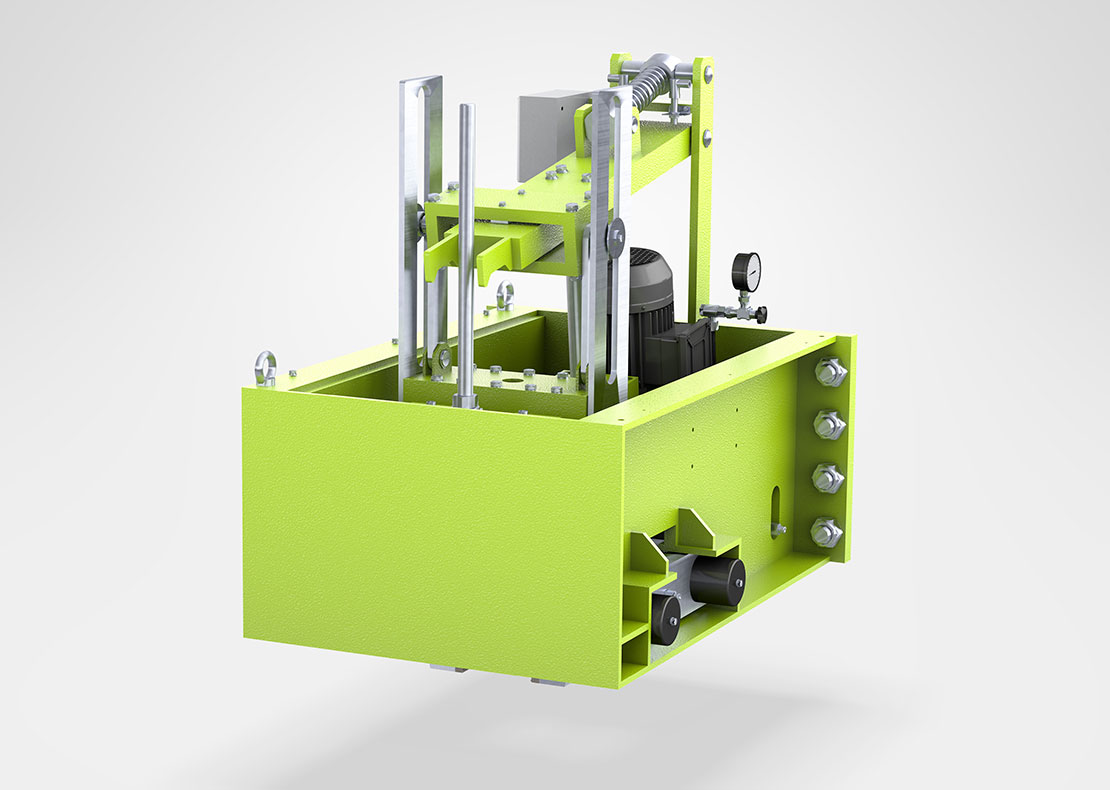

The DB hydraulic power packs deliver pressure up to 200 bar and can be delivered with optional hydraulic cabinets and electrical terminal boxes.

These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic brakes to stop the crane.

These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic brakes to stop the crane.

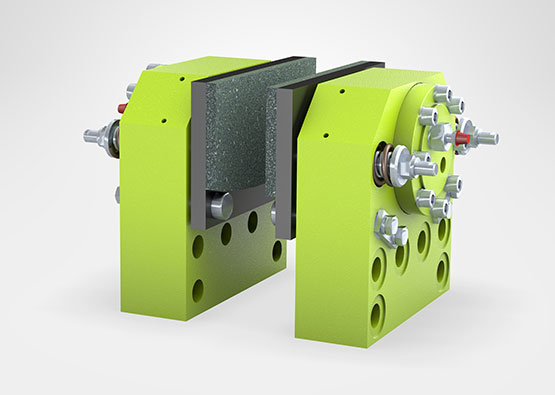

DELLNER BUBENZER's DBSB is a storm safety brake for all rail mounted equipment, e. g. cranes, stackers, reclaimers etc.

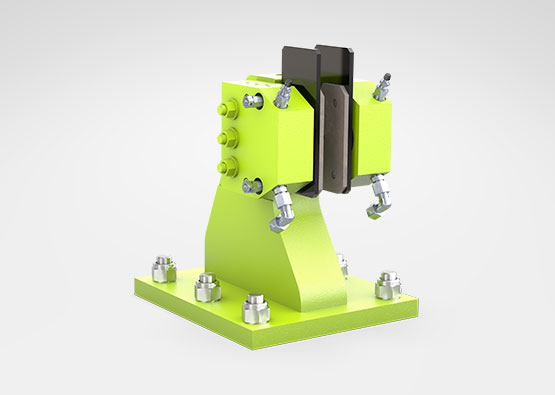

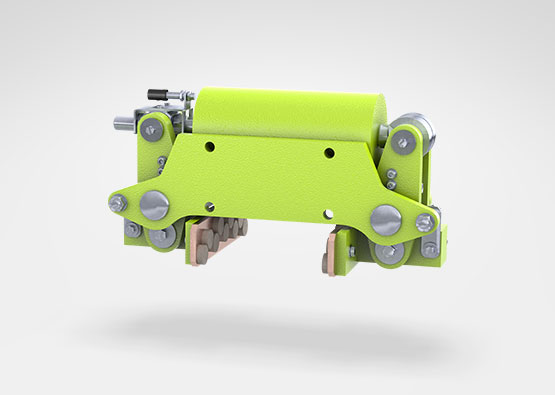

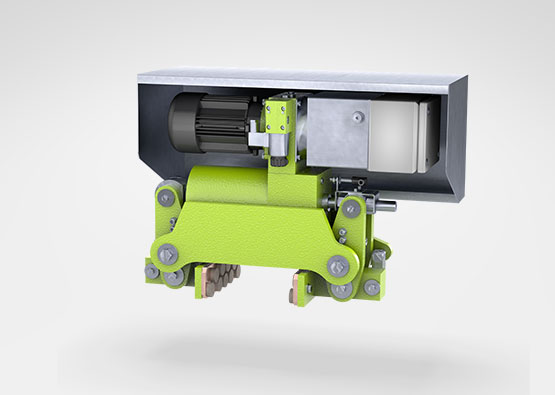

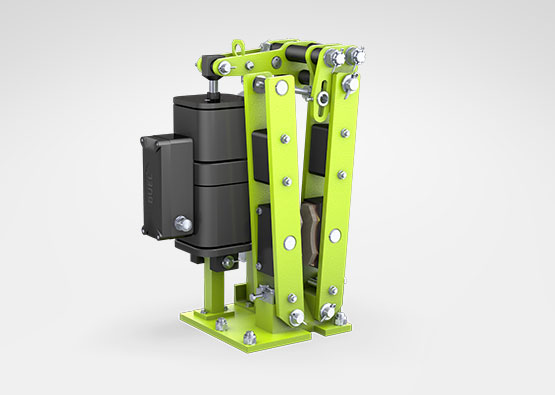

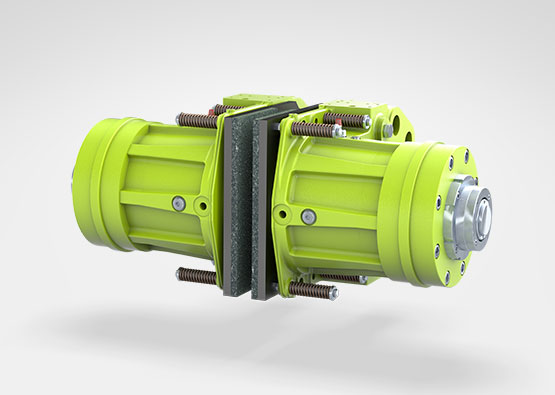

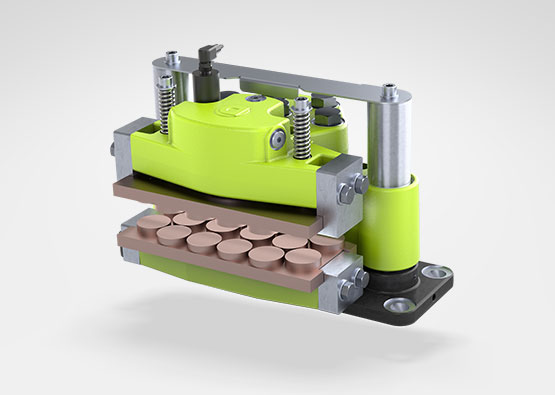

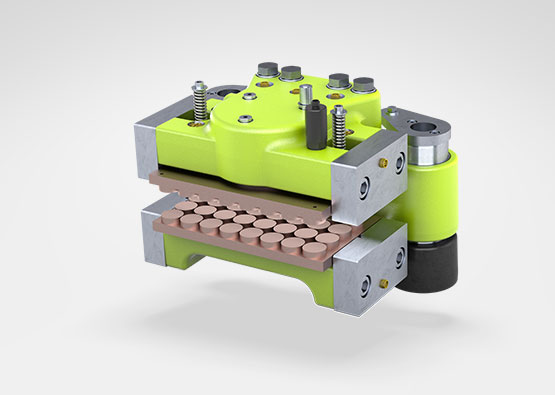

Rail brakes work pressing down on the top of rail by disk springs. Brakes are hydraulically released. Usual parking utilisation requires a few closing / opening cycles per day.

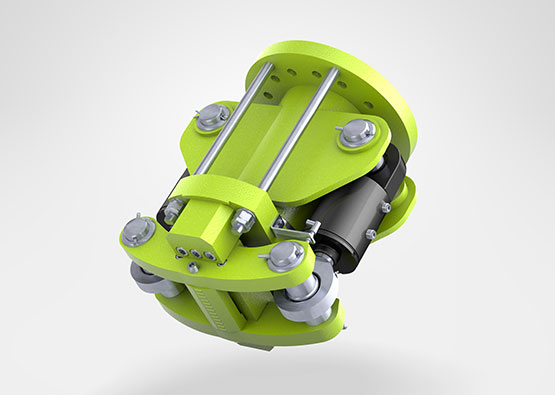

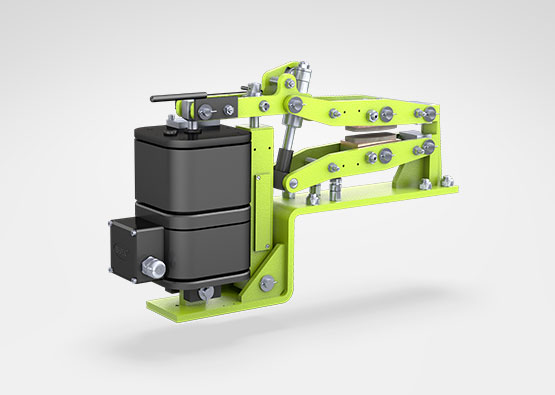

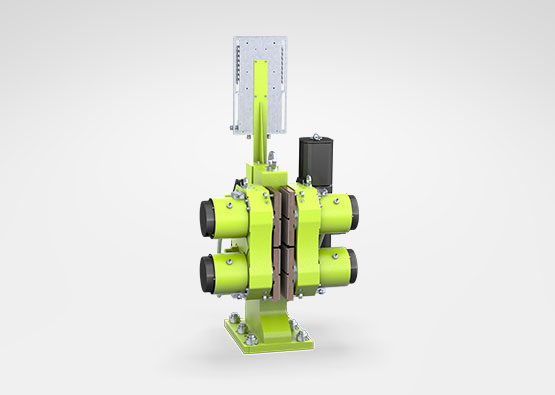

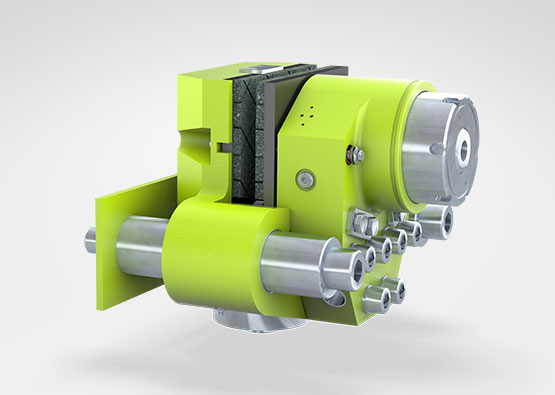

These rail clamps are storm brakes static suitable for small to medium forces. They are spring actuated; the spring exercise the closing force while an hydraulic cylinder fed by a suitable hydraulic unit provides the opening.

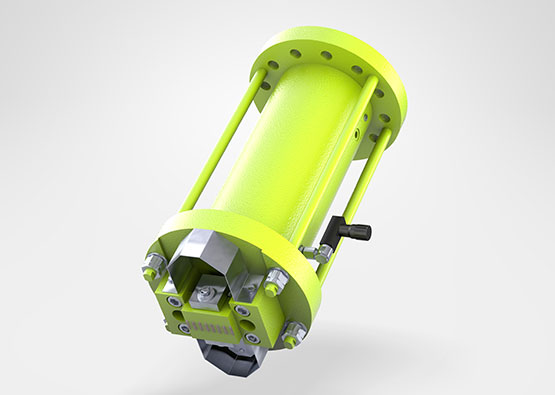

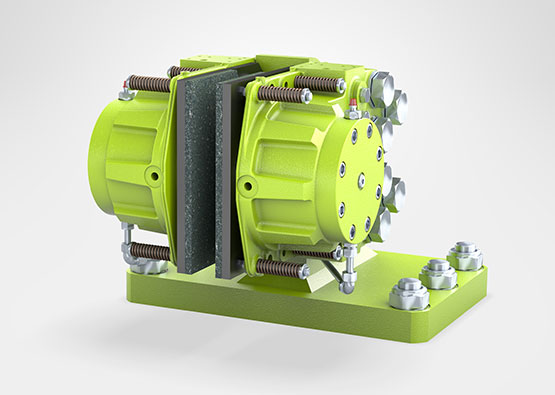

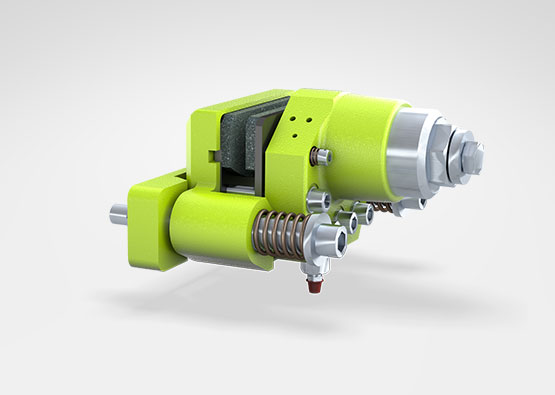

These rail clamps are storm brakes suitable for high forces. They are self-blocking type; in case a force acts on the crane and tends to put the same into motion, they press on the rail sideways.

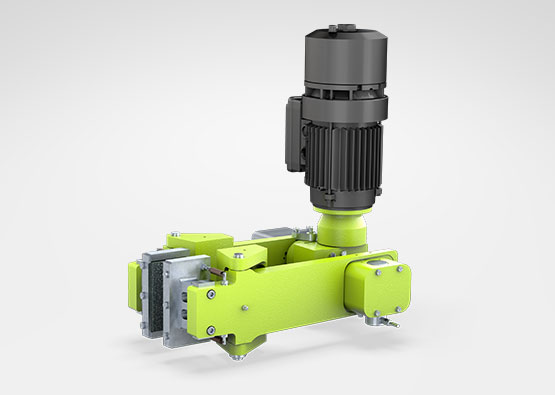

These rail clamps are storm brakes static suitable for small to medium forces. They are spring actuated; the spring exercise the closing force while a group composed by electric motor, gear reducer and a ball screw provides the opening.

These rail clamps are storm brakes suitable for high forces. They are self-blocking type; in case a force acts on the crane and tends to put the same into motion, they press on the rail sideways.

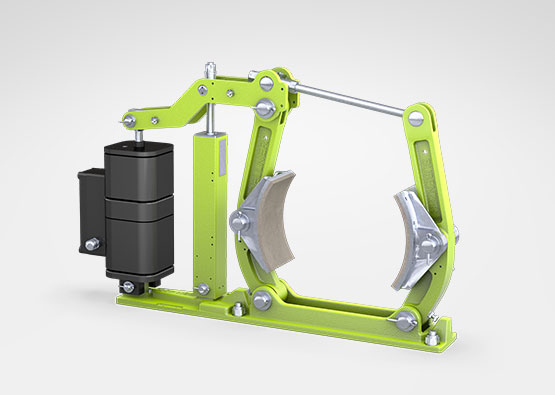

The EBA is a powerful drum brake with braking torques from 24 (ft-lb) to 9000 (ft-lb) that meets AISE (TR11) & NEMA (ICS 8) standards.

The EBH series is designed according to DIN 15435. This design is very compact and can be used in tight motor gearbox combinations.

The EBN series is designed according to DIN 15435 and has been in use in various industries for decades. EBN-2St modification: the drum brakes solution for Bridges and Sluice Systems

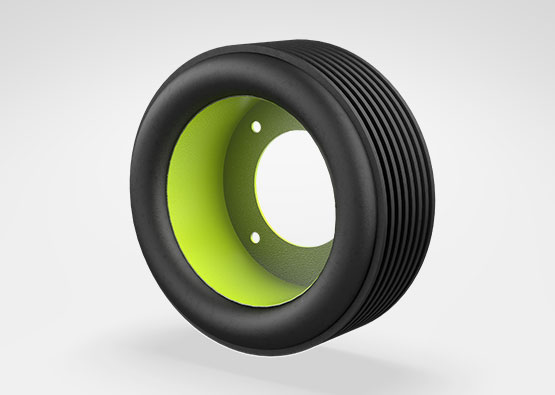

The FKE is best suited for applications with light starting and stopping loads. It is also commonly used as a slip clutch or tension brake within light horsepower and torque applications.

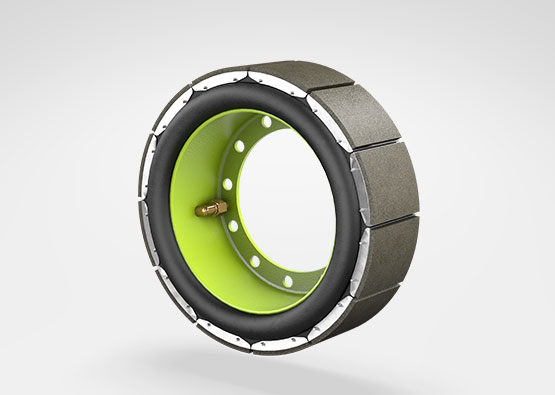

The FKR is often referred to as a coupling, as its expanding neoprene rubber facing engages the interior diameter of the drum directly. The resulting friction generates significant torque within a small package.

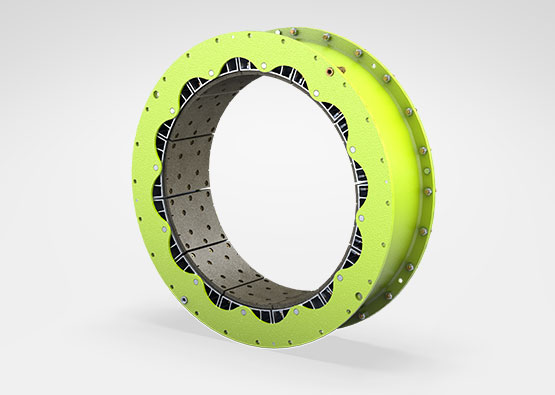

The FK is well suited as a clutch or brake for a variety of high speed and low to medium torque power transmission applications where high heat generation is not a factor.

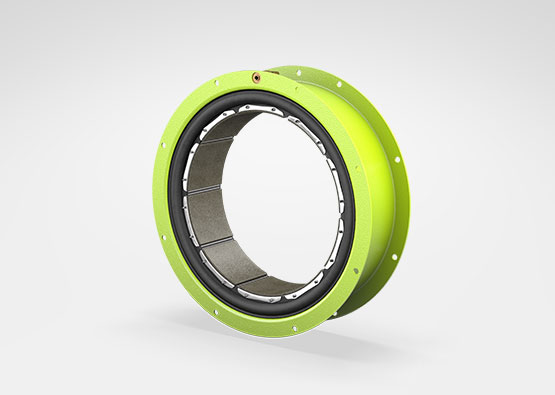

The FKT is well suited for applications with the most demanding equipment where severe clutching and braking is required.

The FM is designed and manufactured for marine applications, mainly for use on diesel-driven reduction gears.

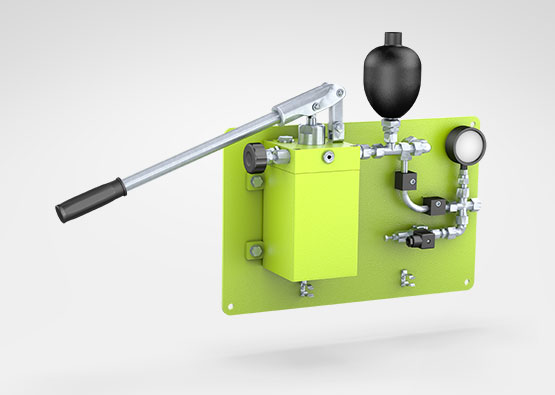

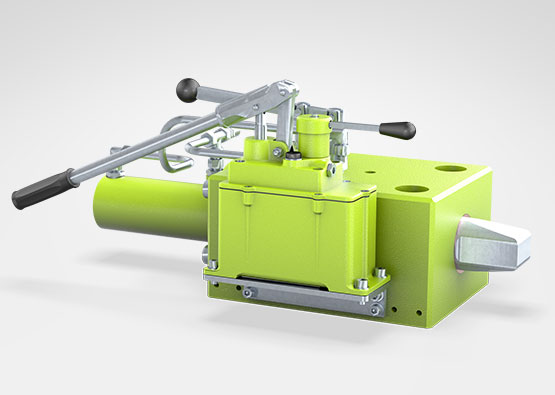

Our hand pump can be used to simply activate the Dellner brake calipers. It also acts as a back up system for the primary pressure supply system.

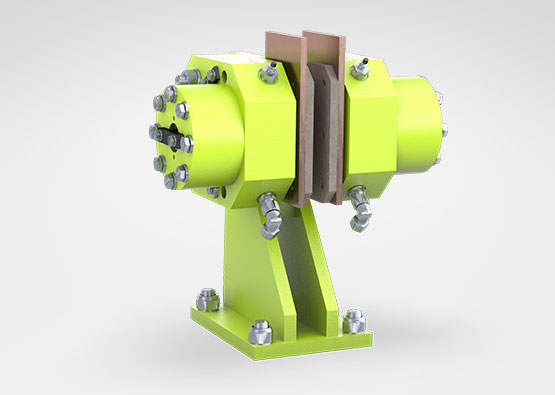

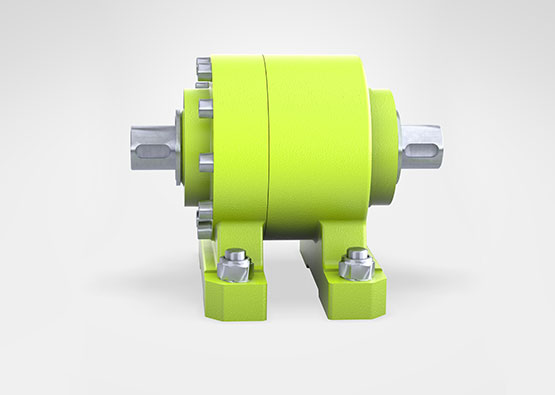

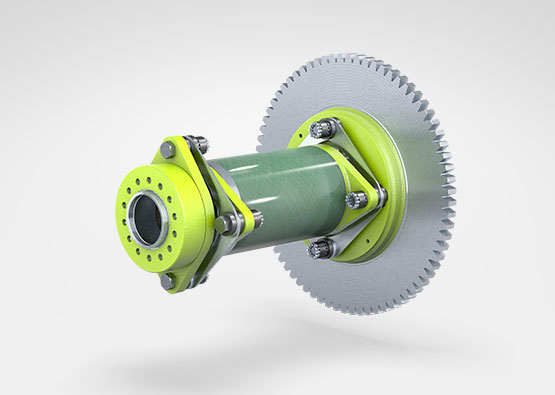

The hydraulic rotary actuator is a device which transform hydraulic power (pressure and flow) in mechanical power: torque and angular speed.

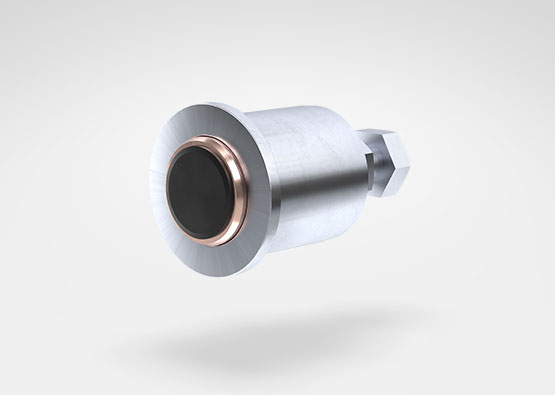

A hydraulic rotor lock offering up to 250 bar pressure with an activation time of 60 seconds.

We offer three models of the JHS-RLH-240 hydraulic rotor lock – the GL Type Certified JHS-RLH-240, the JHS-RLM-240 and the JHS-RLH-240-154. All these locks deliver up to 250 bar pressure with an activation time of just 35 seconds.

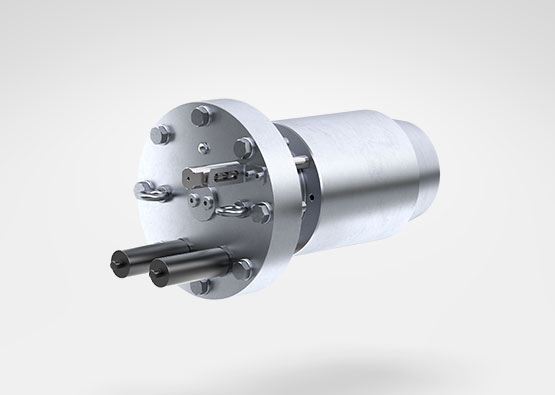

Manually activated rotor lock used for safety purposes during maintenance operations to stop the rotor mechanically. The maximum lateral force is 6400 N and the standard stroke is 95 mm. Other strokes are available upon request.

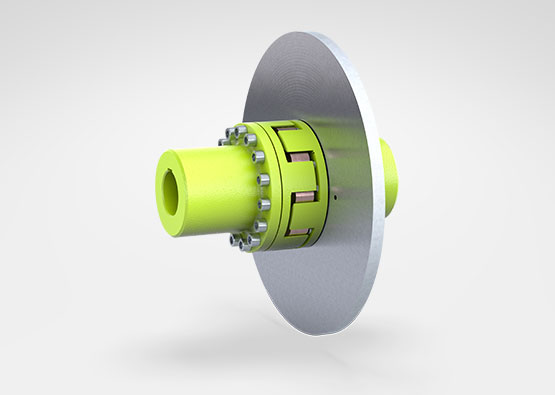

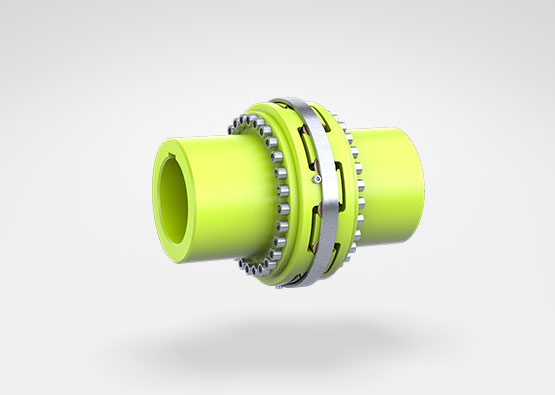

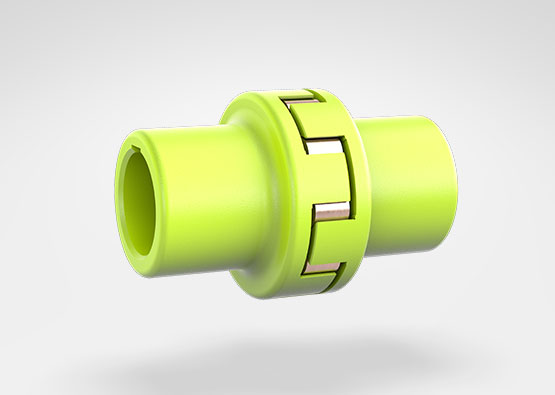

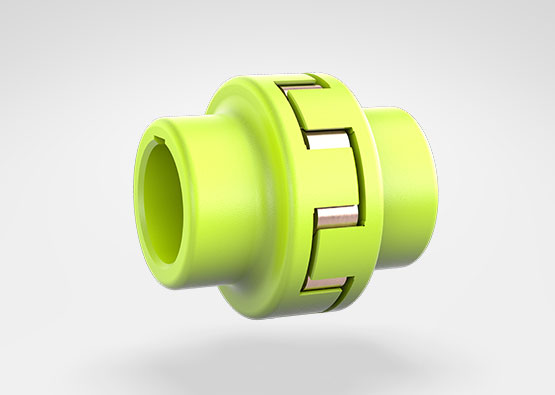

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

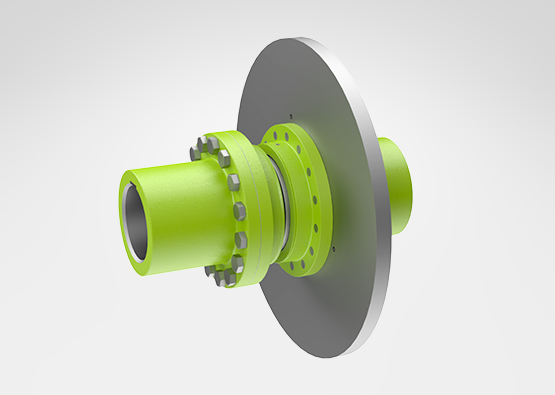

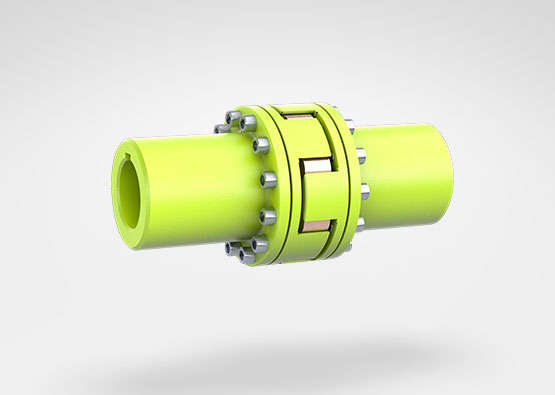

The KBSD Gear Couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

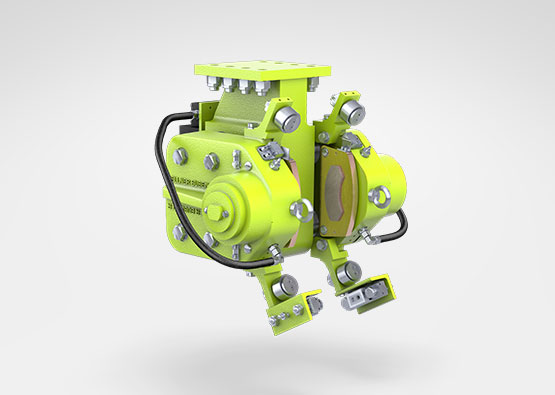

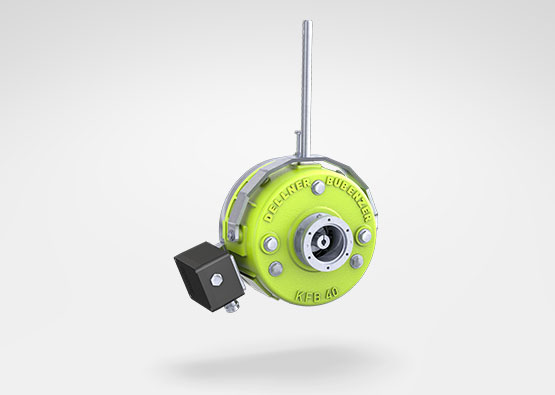

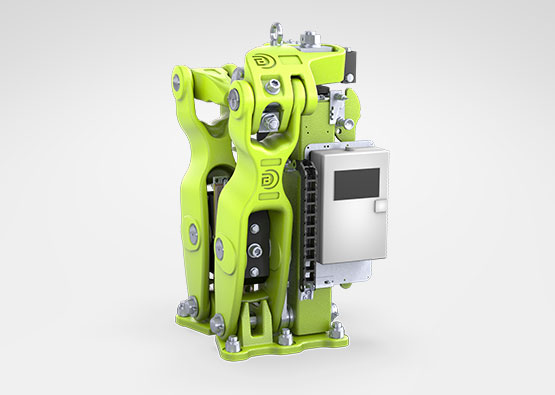

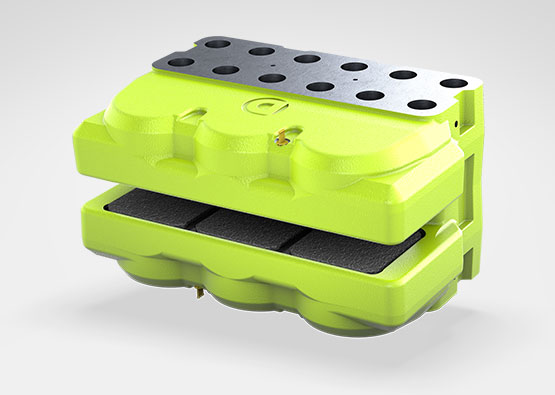

The KFB is a spring applied safety brake which is mainly used in gantry, trolley and hoisting application on harbour crane systems, in dynamic and static use at general industrial applications, in mechanical engineering, steel mills, coal mining or wind energy systems.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

Models within LM series (locking devices) are fail safe and used to mechanically lock a rotational or linear application in a controlled position.

Models within LM sere (locking devices) are fail safe and used to mechanically lock a rotational or linear application in a controlled position.

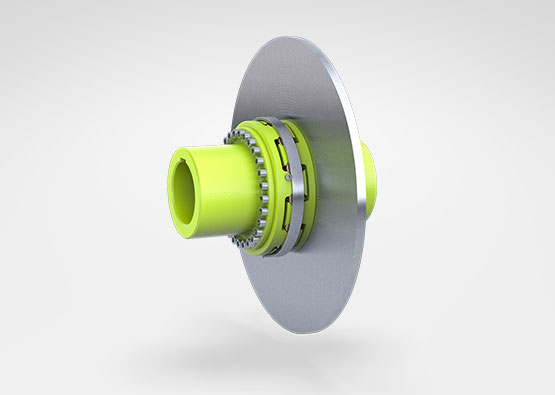

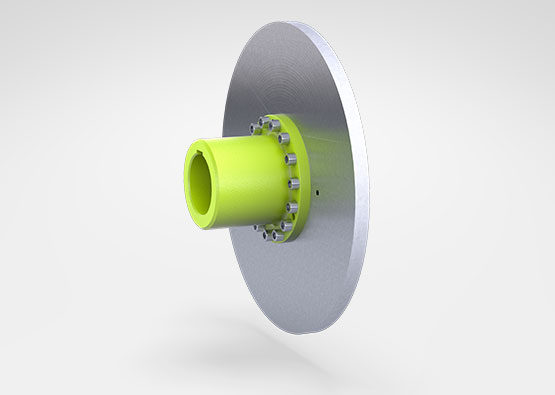

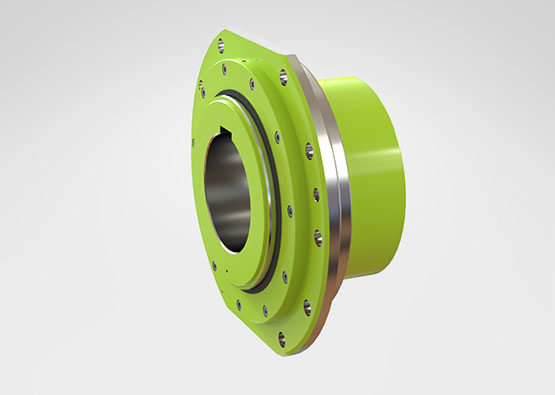

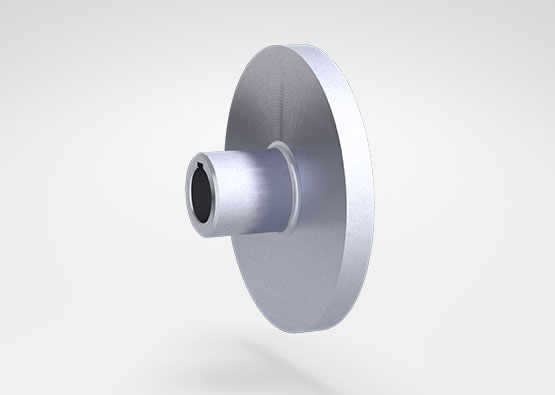

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

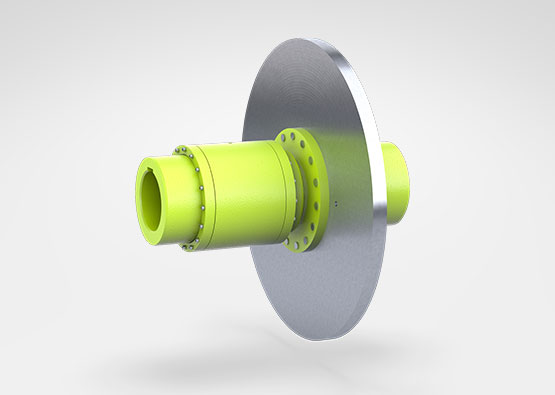

The NTRST Drum Couplings is a high-performance solution for hoist, winches, and conveying systems, ensuring a reliable connection between the gearbox output shaft and the rope drum. Designed to compensate for misalignments caused by bending drum structures, it enhances equipment lifespan and reduces wear.

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

The SB 16 brake has a very compact design and is often used on trolleys for container gantry cranes, RTG and RMG equipment

The SB 17.3 MX brake is a spring-actuated, magnetic-return disc brake for trolley applications on container gantry cranes and other port logistics equipment. Furthermore, the very compact design results in a range of industrial applications in various industries

The SB series stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

The SB 22 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

The SB 23.3 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

Supported by decades of engineering, evolution, and innovation, the SB 28.5 brake presents significant advantages with an enhanced and compact design, sustainability, and preeminent performance.

The SB 30 is the most powerful service brake in this series. It is dimensioned for large hoists and for BOSS applications. Furthermore, automatic adjustment, self-centering, jaw parallel adjustment are part of the standard equipment.

The SB 8 series covers a large part of the versatile industrial applications. It is often used in hoists where installation space is limited and can be equipped with a wide range of options.

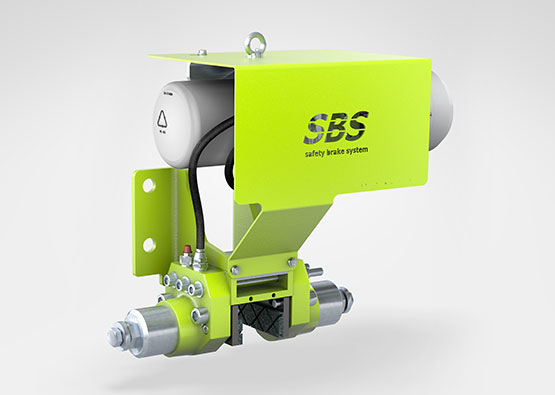

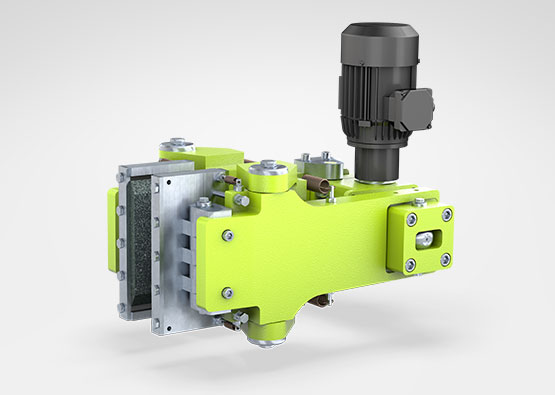

The SBS system consist of a spring applied, hydraulically released SKP model disc brake and the hydraulic brake release pressure is generated from a Hydraulic Power Pack – all incorporated on a bracket. The SBS is typically used on stacker cranes (bolted to crane structure) and the brake is acting directly on the crane travel railhead. The system communicate with the crane control system and can stop the crane wherever in the aisle in an emergency situation.

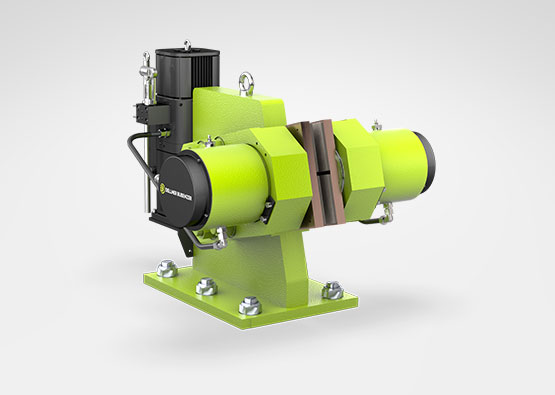

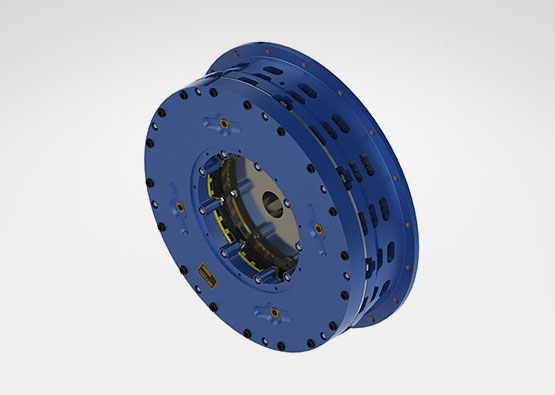

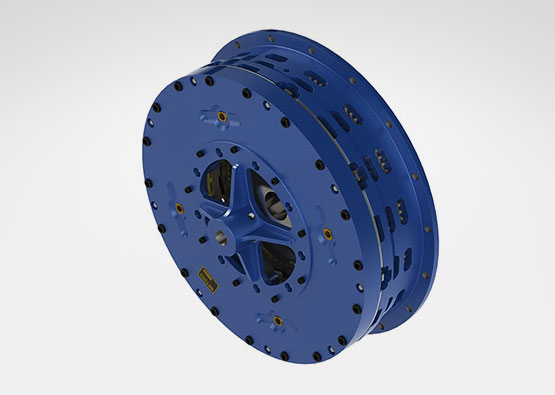

The high capacity of the SF-series makes them particularly suitable as secondary emergency brakes on hoist gears and on downhill conveyors.

The high capacity of the SF-series makes them particularly suitable as secondary emergency brakes on hoist gears and on downhill conveyor.

For many years a seawaterproof version of the SFB series has been used successfully on winch motors in ship building and as a safety, service or holding brake in wharf crane installations.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKDe disc brakes are direct acting electric applied, spring released units.

DELLNER BUBENZER's model SKDe disc brakes are direct acting electric applied, spring released units. The braking force achieved is directly proportional to the applied pressure.

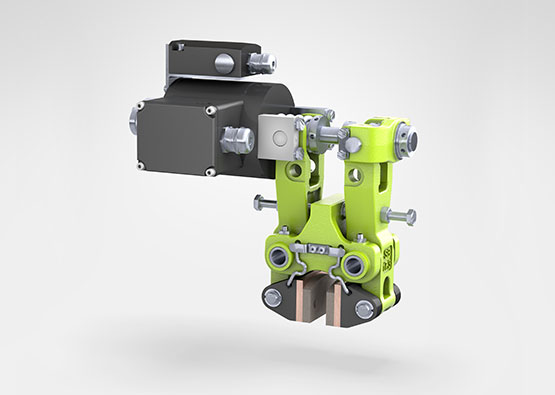

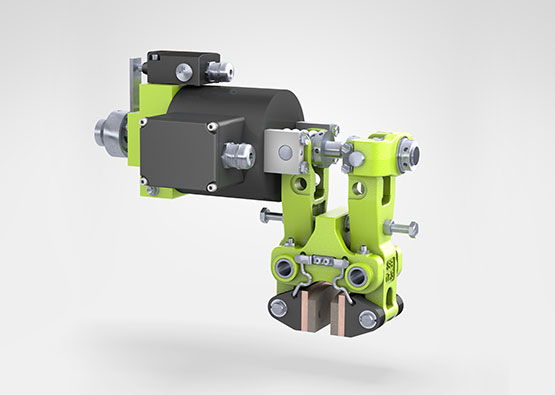

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

With a single acting (SA) brake, braking force is generated in one half of the brake and the other half slides towards it using a robust, low friction system, enabling self-alignment and making it ideal for small spaces and applications with axial movement.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

With a single acting (SA) brake, braking force is generated in one half of the brake and the other half slides towards it using a robust, low friction system, enabling self-alignment and making it ideal for small spaces and applications with axial movement.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

With a single acting (SA) brake, braking force is generated in one half of the brake and the other half slides towards it using a robust, low friction system, enabling self-alignment and making it ideal for small spaces and applications with axial movement.

The STL Systems are "multi-function" units, all contained within one interface. It is indeed a modular system that you can choose the function(s) needed. All from single, S (Stopping) T (Turning) or L (Locking) functions.

The Twin Safe is our larger torque twin disc variation of our classic reliable SFB series, used successfully on winch motors in ship building and as a safety, service or holding brake in wharf crane installations.

A retrofitable, compact electronic status indication system to be integrated into the brake as an additional device.

A hydraulic active rotor brake with a braking force of 44 kN that’s been specially developed for use in damp, dusty and corrosive working environments

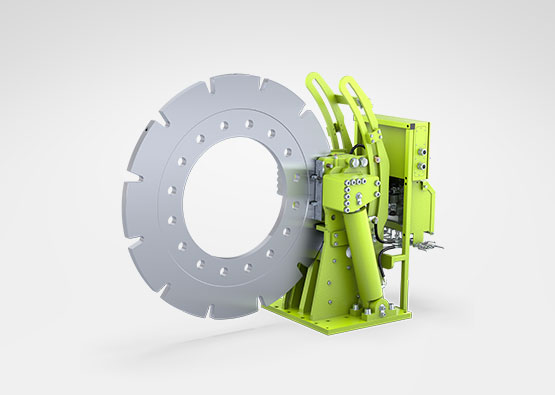

Due to its high capacity, our SFRA brake is mainly used as a rotor brake in wind turbines. It is particularly suitable for applications with a high duty cycle.

Due to its high capacity, our SFRA brake is mainly used as a rotor brake in wind turbines. It is particularly suitable for applications with a high duty cycle.

JHS WTC is a flexible disc coupling mounted between gearbox and generator. It's a tailor-made solution for wind turbine applications (Type WTC = Wind Turbine Coupling).

A hydraulic active yaw brake with GL Type Certification and braking force of 620 kN.

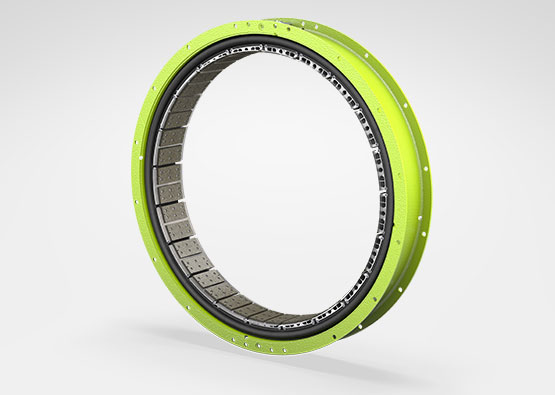

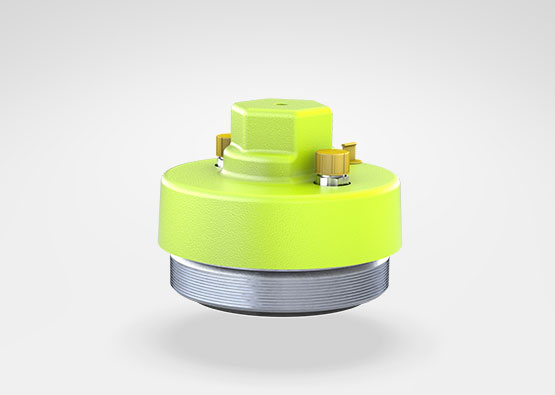

A passive yaw sliding bearing with a robust yet simple design that guarantees optimum performance throughout the life of the turbine.

A passive yaw sliding bearing with a robust yet simple design that guarantees optimum performance throughout the life of the turbine.

Half Wave & Full Wave rectifiers for Din rail or panel mounted rectification.

Gas-hydraulic buffers are installed as impact energy absorber on crane gantries, trolleys, elevators, stackers, reclaimers and other industrial equipment.

Protective element to be connected parallel to the output of the rectifiers BGL, EGL and SGL to increase the interurruption capacity

Din rail mounted unit switches from bridge rectification to half-wave rectification

WPT Low Inertia Brakes are suited for high cycle applications or general brake duties. These heavy duty brakes afford increased precision for your processes with minimal part movement during start and stop, acceleration time is decreased leading to more cycles per minute.

WPT Low Inertia Clutches and Brakes are suited for high cycle applications or general clutch/brake duties.

WPT Low Inertia High Torque Clutches are suited for high cycle applications or general clutch duties.

This flywheel PTO is designed for inline and sideload applications on all internal combustion engines with standard SAE industrial flywheel or flywheel housing dimensions.

WPT Power has engineered the WPT Pilotless™ Mechanical Power Take-off to eliminates the pilot bearing and increases side load capacity over previous generations of PTO products.

Iron & Steel