Pioneering Braking Solutions and More

Featured in: Inside Marine

DELLNER BUBENZER is an industry-diverse global leader in the design and manufacture of braking systems for a wide range of sectors, including crane and hoist, container handling, marine, and offshore, etc. It forms a key part of the DELLNER GROUP, the world leading global suppliers of braking, hydraulic, polymer and glass products. Marine Business Unit Manager Peter Mikaelsson and Head of Marketing Kateryna Prykhodko explained to Hannah Barnett what makes the company so successful.

Peter Mikaelsson, Marine Business Unit Manager, underlined the benefits of DELLNER BUBENZER’s international presence: “There is a significant benefit to having a global footprint especially when it comes to support services and local content requirements. We are a Swedish-owned company, with extensive operations also in Germany, but our presence extends around the world.”

A global operation The company’s roots can be traced back to 1937, but it was not until 2021 that Pintsch Bubenzer and Dellner Brakes merged and DELLNER BUBENZER was born. Products have evolved over time and, on the marine side, the introduction of the innovative Stopping, Turning and Locking (STL) system 20 years ago was game-changing for the company the Marine Business Unit, and the wider sector.

The combination of global manufacturing leadership, and a commitment to service at a local level, makes DELLNER BUBENZER the world’s first choice for sustainable braking solutions and installations. As an international operation, the company is constantly expanding.

DELLNER BUBENZER now has 10 locations around the world, as well as an HQ in Borlänge, Sweden. The company has over 360 employees, including a large and accomplished service team of more than 50 individuals. “The size and scope of our after-sales team is unique, if we compare it with competitors,” said Kateryna Prykhodko, Head of Marketing. “We can offer our customers inspections and maintenance, training, original spare parts and retrofit projects.”

The company runs service centres in Benelux, Germany, Malaysia, Sweden, the USA and the Middle East, providing support for customers around the world. Local content requirements have seen DELLNER BUBENZER investing heavily from a corporate level to meet these standards.

Meanwhile, the marine operation is based in Sweden, where things are also expanding. This includes a recent move to a new location, near to the previous site but with triple the square meterage, to cope with current and future demand from the market.

“We had a substantial operation where we were, but we expect an increase,” said Mr Mikaelsson. “That’s why we have tripled the space. Four years ago, the naval marine sector was a rising star on the horizon. Today, I would say it is a very important portion of our operation. Our long-term experience and knowledge about high-precision performance requirements and reliability helps us a lot within the marine segment.”

DELLNER BUBENZER is now aiming to be more sustainable in all operations. As part of the wider group, the company begun a thorough reporting policy in 2024. Key points of optimisation include employee safety, engineering management, transportation and product design.

“We’re determined to grow as a sustainable company,” Ms Prykhodko said. “In heavy industry, these goals aren’t always easy to reach, but we’re making real progress. And already, I believe our impact is a very positive one.”

Always Improving

Listening and responding to the needs of customers is inherent to the DELLNER BUBENZER ethos. The company’s skilled engineers constantly strive to find and fill gaps in the market. This focus has led to the installation of over 100 unique STL system designs in various marine propulsion platforms.

“We have a wide range of products within the portfolio, and our engineers are constantly improving designs and filling gaps in the range, Mr Mikaelsson explained. “That’s normal for us. It’s very important to listen to customer requirements. This is because it’s not our engineering department that drives innovation; it’s the marketplace.”

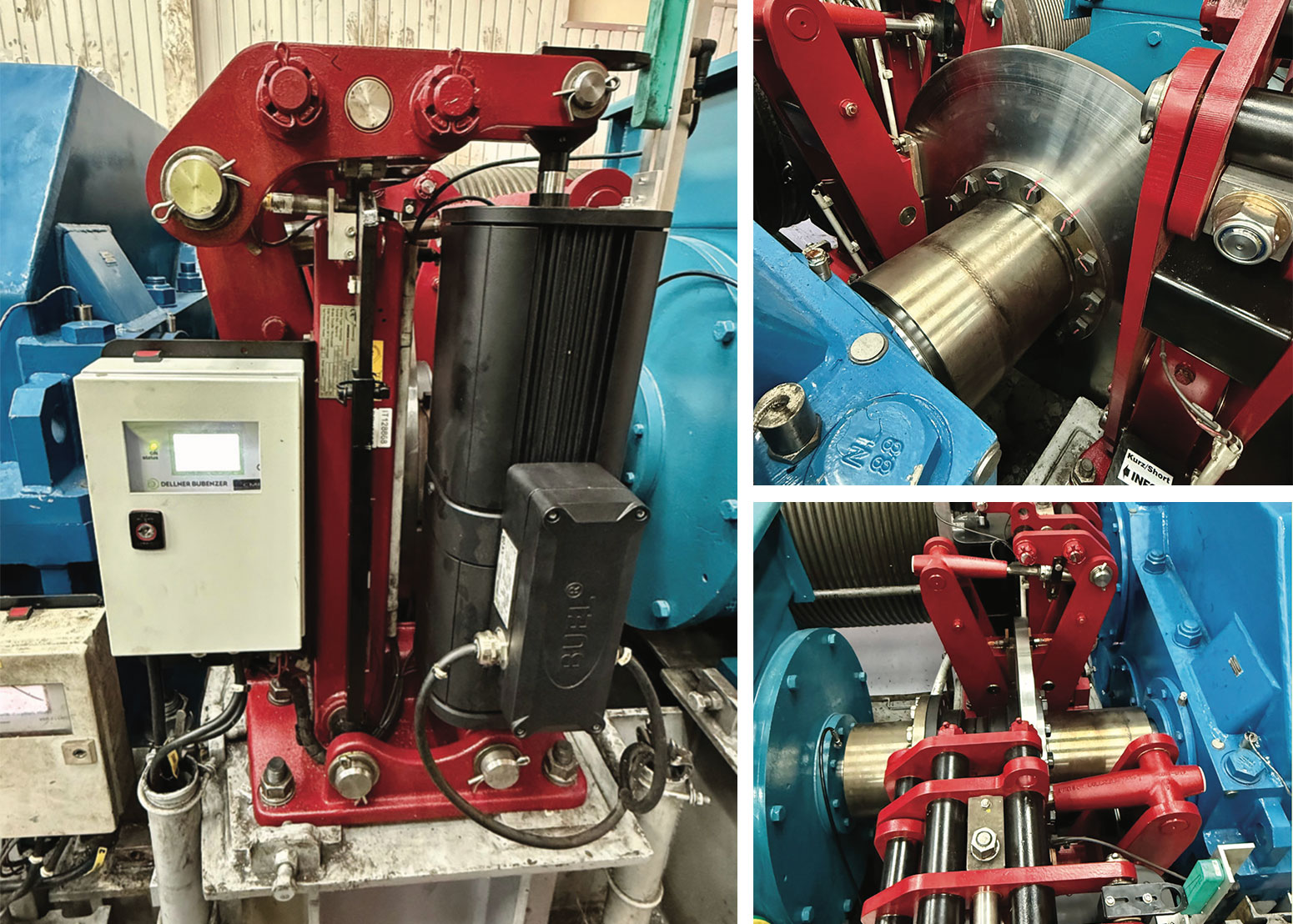

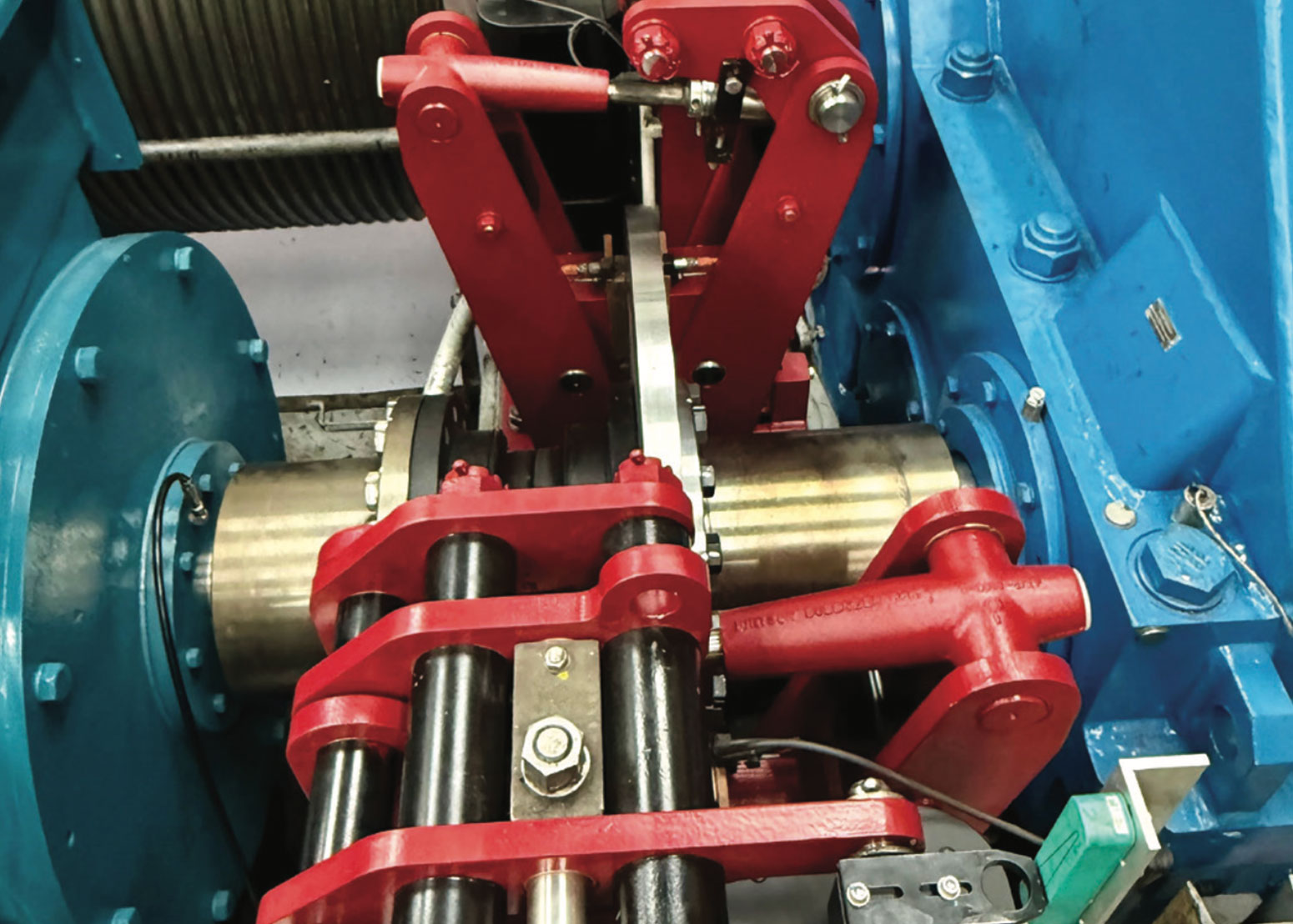

In early 2025, the company started a mid-life overhaul programme in the Netherlands for one of its key customers, based at what is known as the Benelux site. The targeted retrofit project combines modern technology with proven, reliable components - ensuring operational continuity while optimising lifecycle costs.

“This project is a really big one, involving 13 cranes in total,” said Ms Prykhodko. “Of those 13, we are working on 10 quay cranes and three barge quay cranes, and installing a thorough upgrade of their braking and coupling systems.”

The project involves the installation of new BUEL H thrusters to provide greater operational precision and improved adaptability to dynamic hoist demands. It will also see the disc brake replacement of the key wear parts, including bushings, pins and compression springs. New protective coatings are being applied to extend brake service life and durability. The cranes will also be upgraded from KBT 19 couplings to KBSD 190 couplings, reducing maintenance time. The Benelux project is currently ongoing and scheduled for completion in 2026.

“We are also involved in several naval products projects, but everything there comes with strict NDAs,” added Mr Mikaelsson.

“What I can say is that we are currently delivering products to several global frigate programmes. The forecast is looking very promising, and there is a lot happening on the naval side in general.”

Many Moving Parts

Supply chain management is a key factor at the company, especially in Sweden where DELLNER BUBENZER subcontracts all its machining out, despite keeping final assembly and testing in-house. This is because the marine sector has such unique requirements it is impossible to have all competence in-house.

“Our structure favours partners instead of traditional suppliers,” said Mr Mikaelsson. “At the end of the day, it all comes down to relationships. That is the key. Partnership is so important for success in this sector.” Along with the company’s in-house engineering capabilities, it also offers a specialised test location in Germany for R&D. The site is used for experimenting with new products and upgrading old ones and is a unique offering to the market.

“We try to hear our customers and solve their needs,” said Ms Prykhodko. “We also look at what our competitors are doing. None have anything like our test centre in Germany, plus we have a very experienced engineering team who can develop products from scratch. The future will see us expanding into more industries and developing more solutions.”

DELLNER BUBENZER deliberately searches to find new talent, including working closely with local universities. Mr Mikaelsson, having been at the company for over 25 years, knows how important finding the right people is – they are the factor which continues to make DELLNER BUBENZER so dynamic.

“We are a few hundred employees globally, but there is a family atmosphere,” he said, in conclusion. “We look after each other, and we support each other. That motivates me, along with the meetings with our partners and customers. I love having the opportunity to drive our business forward on a global scale.”